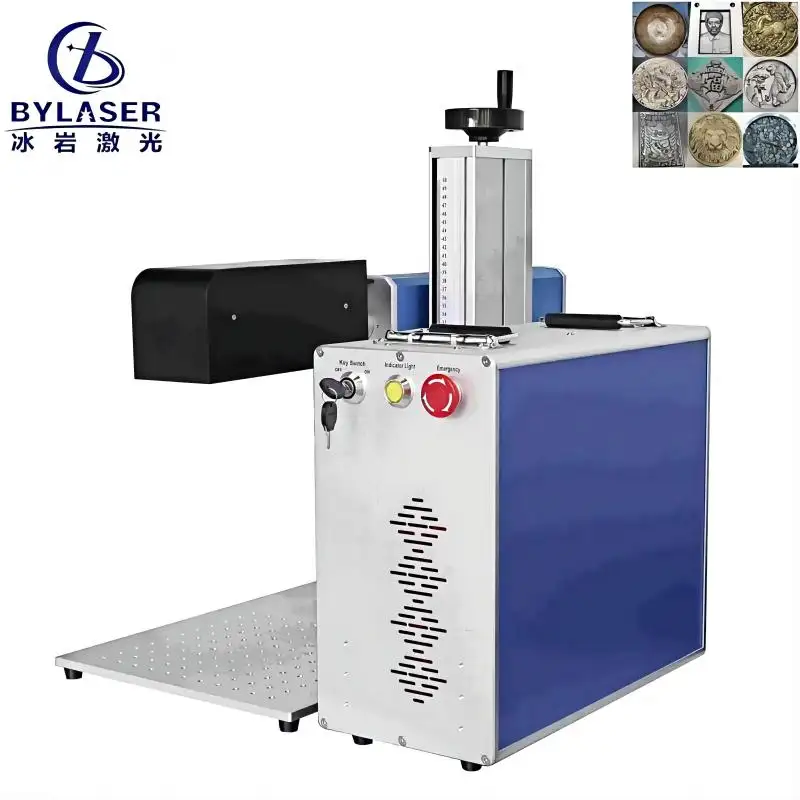

Precision in manufacturing has never been more critical than it is today, with industries demanding increasingly accurate marking, engraving, and identification solutions. A high-quality laser marking machine serves as the backbone of modern producti...

Read more

Industrial cleaning has undergone a revolutionary transformation with the introduction of advanced laser cleaning machine technology. This innovative approach to surface preparation and contamination removal has become increasingly popular across man...

Read more

Industrial metal equipment faces constant challenges from corrosion, rust, and surface contamination that can significantly impact performance and longevity. Traditional cleaning methods often involve harsh chemicals, abrasive materials, or time-cons...

Read more

Choosing the right laser engraver machine requires careful consideration of multiple technical specifications and operational features that directly impact performance, precision, and long-term reliability. Modern manufacturing environments demand eq...

Read more

The jewelry industry has experienced a revolutionary transformation with the introduction of advanced laser engraver machine technology. These precision instruments have become indispensable tools for creating intricate designs, personalizing pieces,...

Read more

Selecting the right fiber laser engraving machine for industrial applications requires careful consideration of multiple technical and operational factors. Modern manufacturing environments demand precision, reliability, and efficiency from their eng...

Read more

Manufacturing industries worldwide are experiencing a revolutionary transformation in metal marking and engraving processes. Traditional engraving methods, while effective for many applications, often fall short when precision, speed, and cost-effect...

Read more

A fiber laser engraving machine represents a significant investment for any manufacturing operation, and proper maintenance is essential to ensure optimal performance throughout its operational lifespan. These sophisticated systems require systematic...

Read more

Which industries gain most from fiber laser engraving? Discover automotive, medical, aerospace, electronics, jewelry & industrial use cases—and boost precision, compliance & ROI. Explore now.

Read more

Struggling with inconsistent engraving results? Discover proven strategies for laser engraver durability, accuracy optimization, and material-specific calibration. Maximize ROI—download the full guide now.

Read more

To Whom It May Concern,This is to formally announce that Mr. Wang Chen, formerly an employee of the Finance Department, has completed all required offboarding procedures. His employment with our company was terminated effective December 12, 2025.Plea...

Read more

Discover why laser rust removal outperforms sandblasting in precision, safety, and long-term cost. Reduce waste and boost efficiency. Learn more now.

Read more