Manufacturing industries today demand precision, speed, and versatility in their marking and engraving operations. Modern fiber laser engraving machines have revolutionized how businesses approach product identification, branding, and customization across diverse sectors. These advanced systems deliver exceptional accuracy while maintaining cost-effectiveness, making them indispensable tools for companies seeking competitive advantages in their respective markets.

The automotive sector relies heavily on precise component marking for quality control and regulatory compliance. Fiber laser engraving machines excel at creating permanent identification marks on various automotive parts including engine components, chassis elements, and electronic modules. These markings withstand extreme temperatures, chemical exposure, and mechanical stress throughout the vehicle's operational lifetime.

Automotive manufacturers utilize these systems to engrave VIN numbers, part numbers, and batch codes directly onto metal surfaces. The non-contact nature of laser engraving eliminates the risk of mechanical damage that traditional marking methods might cause to delicate components. This capability proves particularly valuable when working with lightweight aluminum alloys and advanced steel compositions commonly used in modern vehicle construction.

Premium automotive brands increasingly employ fiber laser engraving machines for customizing interior elements and exterior trim pieces. These systems create sophisticated logos, decorative patterns, and personalized text on various materials including metals, plastics, and composites. The precision achievable with laser technology enables manufacturers to maintain consistent brand aesthetics across different model lines.

Aftermarket automotive suppliers also benefit significantly from laser engraving capabilities. Custom wheel manufacturers, performance parts producers, and accessory companies use these machines to add distinctive branding and decorative elements that enhance product appeal and market differentiation.

Electronics manufacturing demands exceptional precision in component identification and circuit board marking. Fiber laser engraving machines provide the accuracy required for marking microscopic components without affecting their functionality. These systems create clear, permanent marks on semiconductor packages, connectors, and printed circuit boards while maintaining the integrity of sensitive electronic circuits.

The technology industry benefits from the ability to mark various substrate materials including ceramics, metals, and specialized polymers used in electronic device construction. Manufacturers can engrave serial numbers, compliance marks, and technical specifications directly onto components, ensuring traceability throughout the supply chain and facilitating quality assurance processes.

Consumer electronics companies utilize fiber laser engraving machines for personalizing smartphones, tablets, laptops, and wearable devices. This capability allows brands to offer customized products that appeal to individual consumer preferences while maintaining manufacturing efficiency. The versatility of fiber laser systems enables engraving on various materials commonly used in electronic devices including aluminum, titanium, and engineered plastics.

Gaming peripheral manufacturers and computer hardware companies also leverage laser engraving technology to create distinctive visual elements on their products. Custom keyboards, gaming mice, and computer cases often feature intricate designs and branding elements created through precise laser engraving processes.

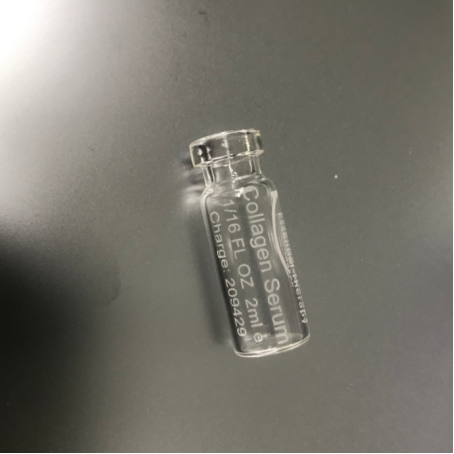

Medical device manufacturing requires absolute precision and compliance with stringent regulatory standards. Fiber laser engraving machines provide the accuracy and reliability necessary for marking surgical instruments, implantable devices, and diagnostic equipment. These systems create permanent, biocompatible markings that withstand sterilization processes while maintaining legibility throughout the product's service life.

Orthopedic implant manufacturers rely on laser engraving technology to mark titanium and stainless steel components with essential information including part numbers, lot codes, and regulatory compliance marks. The precision achievable with modern fiber laser systems ensures that markings remain clear and readable even on curved surfaces and complex geometries typical of medical implants.

The medical industry's emphasis on traceability makes fiber laser engraving machines essential tools for device manufacturers. These systems enable the creation of unique device identifiers and data matrix codes required by regulatory agencies worldwide. The permanent nature of laser markings ensures that critical information remains accessible throughout the device's lifecycle, supporting recall procedures and quality investigations when necessary.

Laboratory equipment manufacturers also utilize laser engraving technology to mark analytical instruments, sample containers, and testing apparatus. The chemical resistance of laser-engraved markings proves particularly valuable in laboratory environments where equipment may be exposed to corrosive substances and cleaning agents.

Aerospace manufacturing demands the highest levels of quality control and component traceability. Fiber laser engraving machines meet these requirements by providing permanent marking capabilities that withstand extreme environmental conditions including temperature variations, pressure changes, and chemical exposure. Aircraft components marked with laser engraving technology maintain their identification throughout decades of service.

Defense contractors utilize these systems for marking weapons components, communication equipment, and specialized military hardware. The security advantages of laser engraving include the difficulty of altering or removing markings without obvious evidence of tampering. This characteristic proves essential for maintaining chain of custody and preventing unauthorized modifications to critical defense systems.

The aerospace industry's focus on weight reduction drives the adoption of advanced materials including carbon fiber composites, titanium alloys, and specialized ceramics. Fiber laser engraving machines adapt well to these diverse materials, providing consistent marking quality across different substrate types. The non-contact nature of laser processing eliminates concerns about introducing stress concentrations or material weakening that mechanical marking methods might cause.

Satellite manufacturers and space technology companies benefit from the precision and reliability of laser engraving systems when marking components destined for space applications. The vacuum compatibility and outgassing characteristics of laser-marked surfaces meet the stringent requirements for spacecraft components and instruments.

The jewelry industry has embraced fiber laser engraving machines for their ability to create intricate designs and personalized markings on precious metals. These systems enable jewelers to engrave complex patterns, text, and images with exceptional detail on gold, silver, platinum, and other valuable materials. The precision achievable with modern laser technology surpasses traditional hand engraving methods while maintaining the artistic quality that luxury consumers expect.

Watch manufacturers utilize laser engraving for creating dial markings, case decorations, and movement component identification. The technology enables the production of consistent, high-quality markings that enhance both the aesthetic appeal and functional aspects of timepieces. Luxury watch brands particularly value the ability to create unique serial numbers and authentication marks that help combat counterfeiting.

Consumer demand for personalized luxury goods has driven widespread adoption of fiber laser engraving machines in retail jewelry stores and custom manufacturing facilities. These systems enable rapid turnaround of personalized items including wedding rings, pendants, and commemorative pieces. The versatility of laser technology allows for engraving various materials commonly used in jewelry making including precious metals, gemstones, and synthetic materials.

Luxury goods manufacturers extend laser engraving applications to leather goods, high-end accessories, and collectible items. The ability to create subtle, sophisticated markings that complement product aesthetics makes fiber laser systems valuable tools for maintaining brand prestige while offering customization options to discerning customers.

Heavy industrial equipment requires permanent identification markings that survive harsh operating environments. Fiber laser engraving machines provide the durability needed for marking construction equipment, mining machinery, and manufacturing tools. These markings remain legible despite exposure to dirt, chemicals, high temperatures, and mechanical abrasion typical in industrial applications.

Oil and gas equipment manufacturers rely on laser engraving technology to mark valves, fittings, and pipeline components with critical information including pressure ratings, material specifications, and manufacturing dates. The corrosion resistance of laser-engraved markings proves essential in petrochemical environments where traditional marking methods might fail prematurely.

Manufacturing facilities utilize fiber laser engraving machines for creating process documentation and quality control markings directly on products and components. These systems enable the integration of manufacturing data including production dates, inspector identification, and quality test results into permanent product markings. This capability supports continuous improvement initiatives and facilitates root cause analysis when quality issues arise.

Tool and die manufacturers benefit from laser engraving technology for marking cutting tools, molds, and production fixtures with identification information and usage tracking data. The precision and permanence of laser markings support asset management programs and help optimize tool replacement schedules based on actual usage patterns.

Fiber laser engraving machines excel at processing various metals including stainless steel, aluminum, titanium, brass, and copper. They also work effectively on certain plastics, ceramics, and composite materials. The specific material compatibility depends on the laser wavelength and power specifications of the particular system being used.

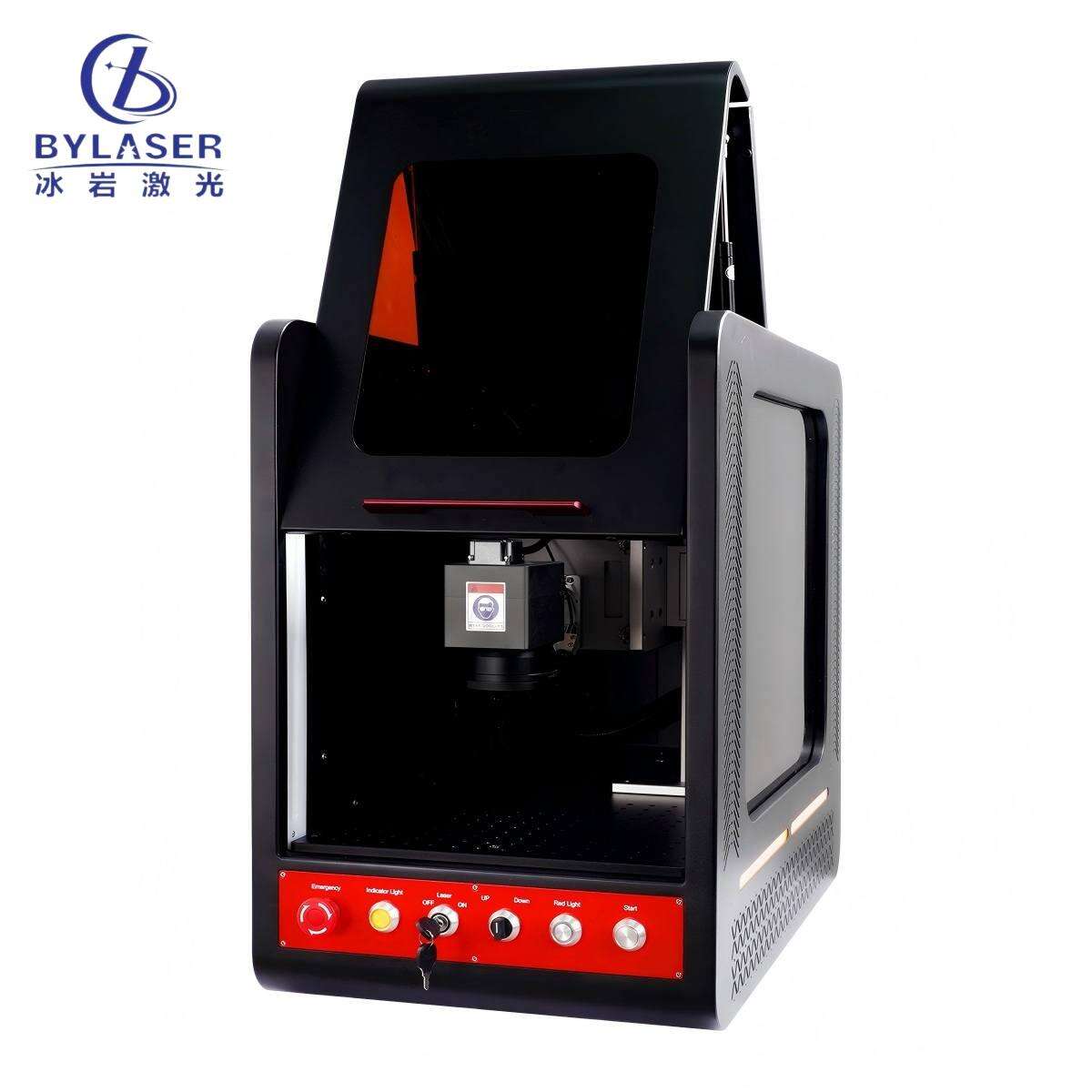

Fiber laser engraving machines typically operate significantly faster than traditional mechanical engraving or chemical etching methods. They can complete complex markings in seconds rather than minutes, and their non-contact operation eliminates tool wear and maintenance requirements associated with mechanical marking systems. This efficiency translates to lower per-part marking costs and higher production throughput.

Modern fiber laser engraving machines require minimal maintenance compared to other industrial marking systems. Regular cleaning of protective windows and periodic calibration checks represent the primary maintenance tasks. The solid-state nature of fiber laser technology eliminates many wear components found in traditional laser systems, resulting in lower operating costs and higher reliability.

Yes, fiber laser engraving machines are well-suited for high-volume production environments. They can operate continuously with minimal downtime, and modern systems often feature automated material handling capabilities. The speed and consistency of laser engraving make these machines ideal for applications requiring thousands of parts to be marked daily while maintaining consistent quality standards.