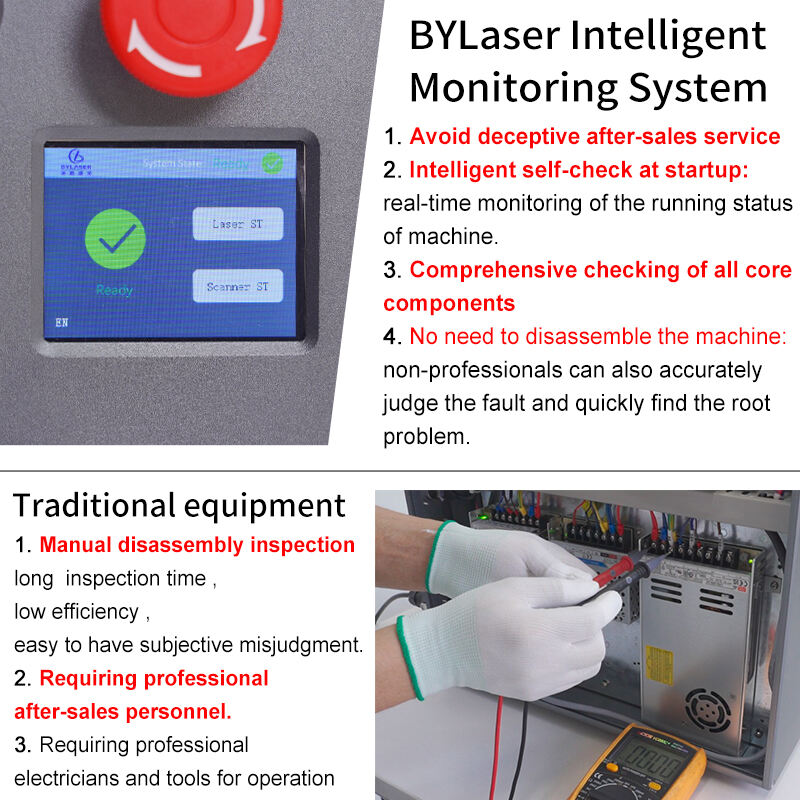

By Laser advanced intelligent monitoring laser marking machine offers superior marking accuracy with real-time monitoring.

Intelligent self-test at start-up: real-time monitoring of the machine's operating status. Comprehensive inspection of core components to ensure that the Laser marking machine is always in the best working condition. Intelligent analysis, so that the maintenance is more timely, effectively avoiding the loss of downtime, and improving production efficiency.

Advantages of Laser Marking Machines Equipped with Intelligent Detection Systems:

1. Enhanced Transparency & Trust:

The system eliminates deceptive after-sales service practices by providing objective, data-driven diagnostics, ensuring customers receive honest maintenance recommendations and cost-effective solutions.

2. Proactive Reliability:

Intelligent self-check during startup enables real-time monitoring of machine status, identifying potential issues before operation. This minimizes unexpected downtime and ensures consistent performance.

3. Comprehensive Component Health Assurance:

All core components (e.g., laser source, galvanometer, optics) undergo automated full-spectrum checks, preventing overlooked failures and extending equipment lifespan through timely maintenance alerts.

4 . User-Friendly Troubleshooting:

Non-professionals can pinpoint faults rapidly without disassembly through intuitive error codes and guided diagnostics. This reduces dependence on technical specialists, slashing repair wait times and operational disruptions.

5. Cost Efficiency:

Combines preventive maintenance (via continuous monitoring) and simplified repairs to lower long-term ownership costs, while maximizing productivity through minimized unplanned maintenance intervals.