Experience the latest generation of Desktop Fiber laser marking machines developed by Bingyan Laser, designed for precision, efficiency, and user-friendliness, incorporating cutting-edge technology into an extremely compact and intelligent design. It uses the most advanced technology, equipped with a CCD vision positioning system and automatic focusing system, suitable for high-demand application areas such as electronics, jewellery, precision machinery, automotive parts, medical equipment, and consumer goods. Compared to traditional desktop fibre laser marking machines, it represents a significant leap forward in both appearance and performance.

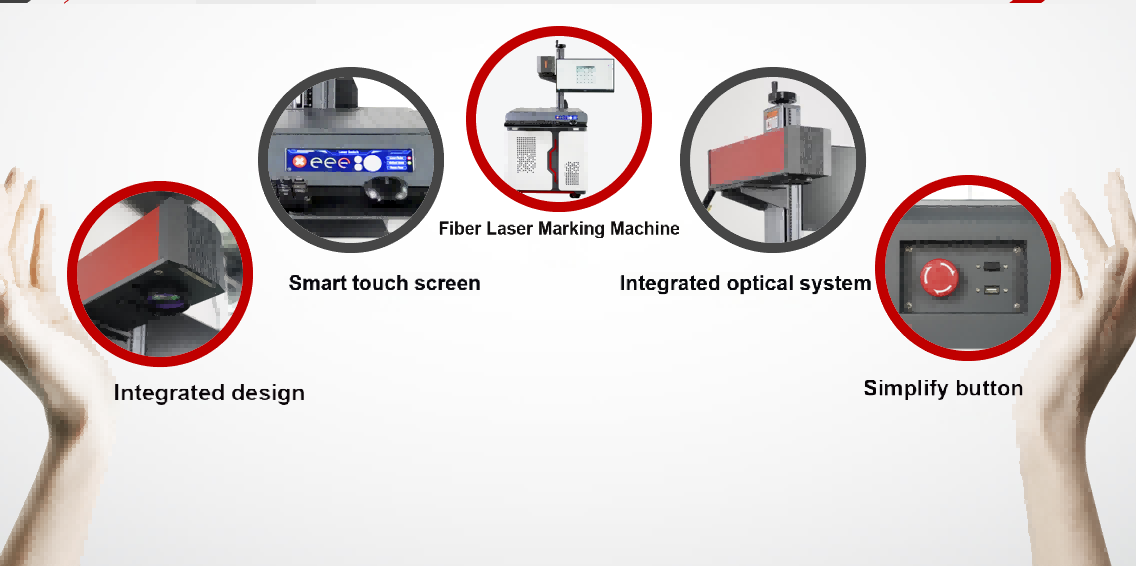

Main Feature:

1. Intuitive Smart Touch Control: High-Resolution Touchscreen: Centralizes full machine operation, parameter setting, and real-time status monitoring. Simplifies workflows and boosts operator efficiency.

2. CCD Visual Positioning System:

True "What You See Is What You Mark": The integrated camera system provides real-time visual feedback directly on the touchscreen. Achieve pinpoint accuracy – simply point to the desired location on the material and mark instantly. Effortlessly handle complex patterns and precise positioning.

3. Automatic Focus:

Rapid Auto-Focus: Achieves precise focus in seconds for consistent mark quality across varying material heights. Drastically reduces setup time.

4. Integrated LED Work Area Illumination:

High-brightness LEDs integrated below the optical path ensure optimal visibility in any lighting condition, guaranteeing precise material placement and mark inspection.

5. Tri-Color Status Indicator:

Prominently located front-facing LEDs (Red /Yellow /Green) provide instant, clear visual confirmation of machine status (Running, Error, Ready/Idle) from a distance.

6. Compact design, revolutionary:

Integrated optical path structure, compact body structure, occupying less than 1 m²; hidden minimalist control panel, combining safety and aesthetics.

7. The bottom features a foam wheel design, which is easy to move and can also be used for horizontal adjustment.

| Laser Type | Fiber Laser |

| Power | 100W /200W /300W |

| Laser Wavelength | 1064nm |

| Laser Source Lifetime | 100,000 hours |

| Cooling System | Air Cooling |

| Operating Temperature | 0-40℃ |

| Operating Humidity | ≦80% |

| Marking Area Range | 70mm - 300mm (Custom Selectable) |

| Positioning Method | Red Beam Indicator |

| Main Controller | JCZ / BSL |

| Net Weight | 110kg |

| Gross Weight | 145 kg |

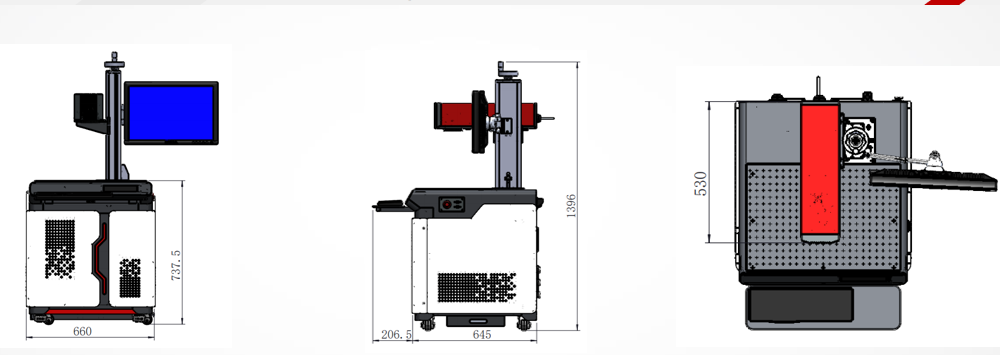

| Machine Dimensions (W x D x H) | 660 x 682 x 737.5 mm (Excluding Column) |

| Packaging Dimensions (W x D x H) | 890 x 750 x 1080 mm |

| Operating system | Windows |

| Interface language | All Major Languages |

| File Import Method | USB Drive |

| Supported File Formats | Bitmap: JPG, PNG, BMP, GIF, TGA, TIF Vector: PLT, DXF, AI, DST, SVG, DWG |

| Supported Marking Types | Text, 2D Barcodes, QR Codes, Geometric Shapes, Vector Graphics, Bitmap Images |

Primary Industry Applications:

1. Precision Electronics & Semiconductor:

Components: PCB marking (serial numbers, barcodes, logos), IC/chip marking, connector labeling, capacitor/resistor coding.

Advantage: Non-contact, high-resolution marking avoids damaging delicate components;

2. Jewelry & Precision Engineering:

Components: Fine metal components, watch parts, bespoke engineering items, jigs, templates.

Advantage: Exceptional precision enabled by vision system and fine beam; suitable for intricate designs and micro-marking; LED illumination reveals fine details.

3. Industrial Tooling & Machinery:

Components: Cutting tools (drills, end mills), gauges, fixtures, molds, dies, machine parts, nameplates.

Advantage: Durable markings withstand harsh industrial environments; high-speed marking for high-volume production

4. Medical Device & Instrument Manufacturing:

Components: Surgical tools, implants (non-active surfaces), diagnostic equipment housings, labware, syringes, packaging

Advantage: Compliant with strict traceability requirements (UDI); biocompatible marking; non-contaminating process; compact design suits controlled environments.

5. Automotive & Aerospace Components:

Components: Engine parts, sensors, valves, transmission components, fuel system parts, VIN plates, aerospace brackets, turbine blades (non-critical).

Advantage: Permanent, wear-resistant markings for traceability (UDI, QR codes, serialization); handles various metals

6. Consumer Goods & Appliances:

Components: Kitchenware, power tools, electronics housings, cosmetic cases, promotional items, luxury goods.

Advantage: High-contrast, aesthetically pleasing marks (logos, graphics via 256-level grayscale); flexibility for various plastics, anodized aluminum, coated surfaces; "WYSIWYM" simplifies custom/limited runs.

7. Hardware & Plumbing Fixtures:

Components: Valves, fittings, faucets, pipes, fasteners, architectural hardware.

Advantage: Permanent markings on stainless steel, brass, copper; resistant to corrosion and cleaning agents; fast cycle times for high-volume items.

8. Packaging & Promotional Materials:

Components: Anodized aluminum boxes, premium gift tins, metal nameplate, certification plaques.

Advantage: High-quality graphics and text for branding; non-damaging to surfaces