Selecting the right fiber laser engraving machine for industrial applications requires careful consideration of multiple technical and operational factors. Modern manufacturing environments demand precision, reliability, and efficiency from their engraving systems. A fiber laser engraving machine represents a significant investment that can transform production capabilities when chosen correctly. Understanding the key specifications, performance characteristics, and compatibility requirements ensures optimal results for your specific industrial applications.

Industrial engraving operations span diverse sectors including automotive, aerospace, electronics, medical devices, and consumer goods manufacturing. Each sector presents unique material challenges and precision requirements that influence machine selection. The versatility of modern fiber laser technology enables processing of metals, plastics, ceramics, and composite materials with exceptional accuracy and speed.

The heart of any fiber laser engraving machine lies in its fiber optic laser source, which generates coherent light through rare-earth-doped glass fibers. This technology offers superior beam quality compared to traditional CO2 or diode laser systems. The concentrated energy beam interacts with material surfaces to create precise engravings, markings, or cuts depending on power settings and processing parameters.

Fiber laser systems typically operate at wavelengths around 1064 nanometers, providing excellent absorption characteristics for most metals and many non-metallic materials. The laser beam travels through fiber optic cables to the processing head, where focusing optics concentrate the energy into a precise spot size. This configuration enables exceptional positioning accuracy and repeatability essential for industrial applications.

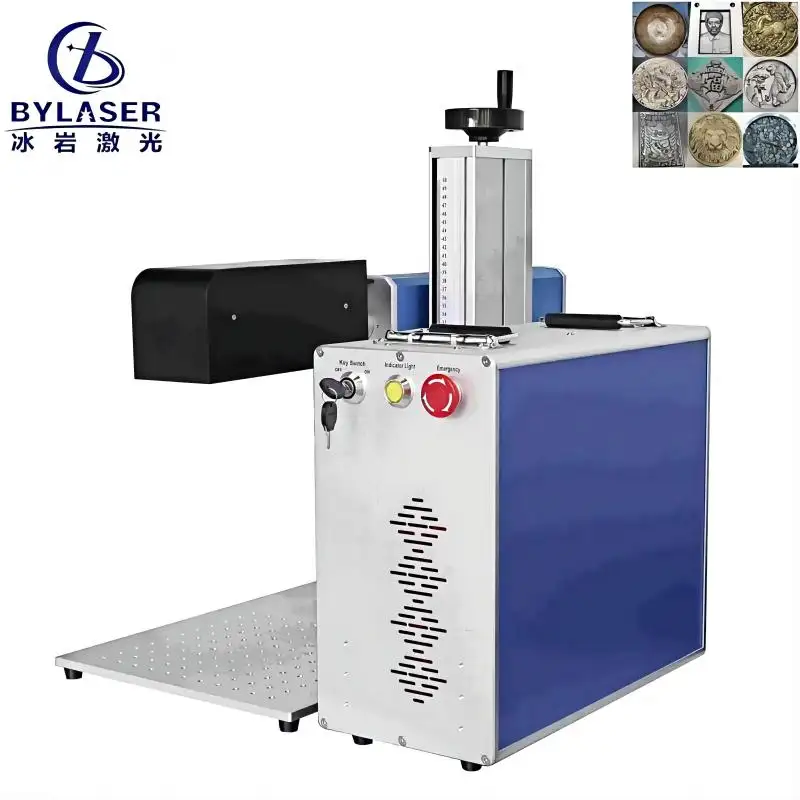

Modern fiber laser engraving machine designs deliver significant advantages over older technologies including reduced maintenance requirements, higher electrical efficiency, and superior beam stability. The solid-state construction eliminates consumable components like gas refills or lamp replacements common in other laser types. Additionally, fiber lasers maintain consistent performance characteristics over extended operating periods.

The compact footprint and modular design of fiber laser systems facilitate integration into existing production lines. Many models feature air-cooled operation, eliminating the need for water cooling systems and reducing installation complexity. These characteristics make fiber laser technology particularly attractive for space-constrained manufacturing environments.

Power selection represents one of the most crucial decisions when specifying a fiber laser engraving machine for industrial use. Available power ranges typically span from 10 watts for fine marking applications up to several hundred watts for deep engraving and cutting operations. Higher power levels enable faster processing speeds and deeper material penetration but require careful consideration of heat management and safety protocols.

Application requirements directly influence optimal power selection. Fine marking of serial numbers, barcodes, or logos typically requires 10-30 watts, while deep engraving applications may need 50-100 watts or more. Material thickness, desired processing speed, and required mark depth all factor into power determination. Consulting with application engineers helps optimize power selection for specific industrial requirements.

The working envelope of a fiber laser engraving machine must accommodate your largest anticipated workpieces while maintaining positioning accuracy across the entire area. Standard working areas range from small desktop formats suitable for electronics components to large-format systems handling automotive panels or architectural elements. Consider both current and future production requirements when sizing the working area.

Positioning accuracy and repeatability specifications directly impact engraving quality and consistency. Industrial applications typically require positioning accuracy within ±0.01mm or better. Advanced servo motor systems with high-resolution encoders ensure precise beam positioning throughout the working area. Some systems incorporate laser interferometer feedback for ultimate positioning accuracy in critical applications.

Fiber laser technology excels at processing various metals including stainless steel, aluminum, brass, copper, titanium, and tool steels. Each material exhibits different absorption characteristics and thermal properties that influence processing parameters. A quality fiber laser engraving machine includes comprehensive material libraries with pre-optimized settings for common industrial alloys and grades.

Surface treatments and coatings can significantly affect laser processing results. Anodized aluminum, painted surfaces, and plated metals each require specific parameter adjustments for optimal results. Advanced systems offer real-time power modulation and beam shaping capabilities to accommodate varying surface conditions within individual workpieces.

While optimized for metals, modern fiber laser engraving machine systems can process many non-metallic materials including engineered plastics, ceramics, and composite materials. Processing parameters require careful optimization to prevent material degradation or unwanted thermal effects. Some materials benefit from specialized beam delivery optics or processing gas environments.

Plastic materials like ABS, polycarbonate, and nylon respond well to fiber laser processing when parameters are properly optimized. Ceramic materials including alumina, zirconia, and silicon nitride can be marked or engraved for identification purposes. Composite materials present unique challenges requiring application-specific testing and parameter development.

Modern industrial environments demand seamless integration between laser engraving systems and existing production equipment. A properly specified fiber laser engraving machine includes comprehensive communication interfaces supporting common industrial protocols including Ethernet/IP, Profinet, and Modbus TCP. These interfaces enable real-time production monitoring and control integration.

Automated material handling systems including conveyor integration, robotic loading, and part positioning fixtures extend system capabilities and reduce labor requirements. Vision systems can provide automatic part recognition and positioning compensation, ensuring consistent results even with manufacturing tolerances in incoming parts.

Comprehensive software packages streamline operation and maximize productivity of fiber laser engraving machine installations. Modern systems include intuitive graphical interfaces supporting direct import of CAD files, automatic toolpath generation, and real-time processing monitoring. Advanced features include barcode and serial number generation, database connectivity for traceability, and remote monitoring capabilities.

Production management features enable job queuing, automatic parameter recall, and statistical process monitoring. Some systems incorporate predictive maintenance algorithms that monitor laser performance and recommend service intervals based on actual usage patterns rather than calendar schedules.

Industrial fiber laser engraving machine installations must comply with laser safety standards including IEC 60825 and applicable regional regulations. Class 4 laser systems require comprehensive safety interlocks, emergency stops, and operator protection measures. Proper beam containment and access control systems prevent accidental exposure to laser radiation.

Fume extraction systems remove processing byproducts and maintain acceptable air quality in the work environment. Material-specific filtration requirements vary depending on processed materials and their potential health impacts. Activated carbon filters handle organic compounds while HEPA filtration removes particulate matter.

Fiber laser engraving machine systems require stable environmental conditions for optimal performance and longevity. Temperature stability within ±5°C helps maintain consistent laser output and mechanical precision. Humidity control prevents condensation issues that could affect optical components or electrical systems.

Vibration isolation may be necessary in facilities with heavy machinery or high foot traffic. Even minor vibrations can affect engraving quality, particularly for fine detail work or precision applications. Proper installation on stable foundations or isolation pads ensures optimal system performance.

Initial purchase price represents only one component of total fiber laser engraving machine ownership costs. Operating expenses include electrical consumption, maintenance supplies, and periodic service requirements. Fiber laser technology typically offers lower operating costs compared to alternative technologies due to reduced maintenance requirements and higher electrical efficiency.

Productivity improvements often justify fiber laser engraving machine investments through reduced cycle times, improved quality consistency, and elimination of consumable tooling costs. Many installations achieve payback periods of 12-24 months through operational improvements and reduced labor requirements.

Equipment financing options include traditional purchase, lease arrangements, and pay-per-use models that align costs with production volumes. Some manufacturers offer comprehensive service packages including preventive maintenance, emergency repair response, and performance guarantees that provide predictable operating costs.

Training programs ensure operators and maintenance personnel understand proper system operation and basic troubleshooting procedures. Comprehensive training reduces downtime risks and maximizes system utilization throughout the equipment lifecycle.

Selecting a reliable fiber laser engraving machine manufacturer requires evaluation of technical capabilities, industry experience, and support infrastructure. Established manufacturers with proven track records in industrial laser applications provide greater assurance of product reliability and long-term support availability.

Application support capabilities including sample processing, parameter development, and ongoing technical assistance significantly impact implementation success. Manufacturers with comprehensive applications laboratories can provide detailed feasibility studies and process optimization services.

Local service availability affects system uptime and operational costs throughout the equipment lifecycle. Evaluate service response times, technician qualifications, and spare parts availability when comparing fiber laser engraving machine suppliers. Remote diagnostic capabilities enable faster troubleshooting and may reduce service call requirements.

Training resources including operator manuals, video tutorials, and hands-on training sessions ensure successful system implementation. Ongoing technical support through phone, email, and web-based resources helps resolve operational questions and optimize processing parameters.

Fiber laser engraving machine systems require minimal routine maintenance compared to other laser technologies. Daily maintenance typically involves cleaning protective lenses and checking consumable items like assist gas supplies. Weekly tasks include inspecting motion system components and verifying safety interlocks. Monthly maintenance covers more comprehensive cleaning and calibration checks, while annual service includes detailed inspection of optical components and replacement of wear items.

Power selection for a fiber laser engraving machine depends on material types, thickness, desired processing speed, and mark depth requirements. Light marking applications on metals typically require 10-30 watts, while deep engraving may need 50-100 watts or more. Material samples processed at different power levels help determine optimal specifications. Consulting with application engineers ensures proper power selection for your specific requirements.

Industrial fiber laser engraving machine installations require comprehensive safety measures including laser safety training, proper beam containment, emergency stop systems, and personal protective equipment. Class 4 laser systems mandate controlled access areas, warning signage, and interlocked safety systems. Fume extraction removes processing byproducts, while proper electrical installation ensures safe operation. Regular safety audits verify continued compliance with applicable regulations.

While optimized for metal processing, many fiber laser engraving machine systems can successfully process non-metallic materials including engineering plastics, ceramics, and composite materials. Processing parameters require careful optimization to prevent thermal damage or unwanted surface effects. Some materials may require specialized beam delivery optics or processing environments. Sample testing determines feasibility and optimal parameters for specific non-metallic applications.