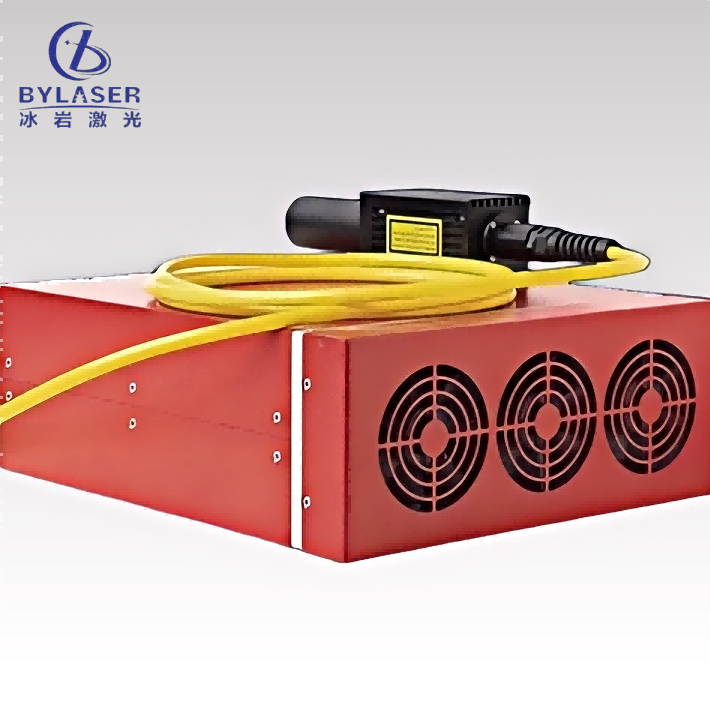

compact laser marking machine

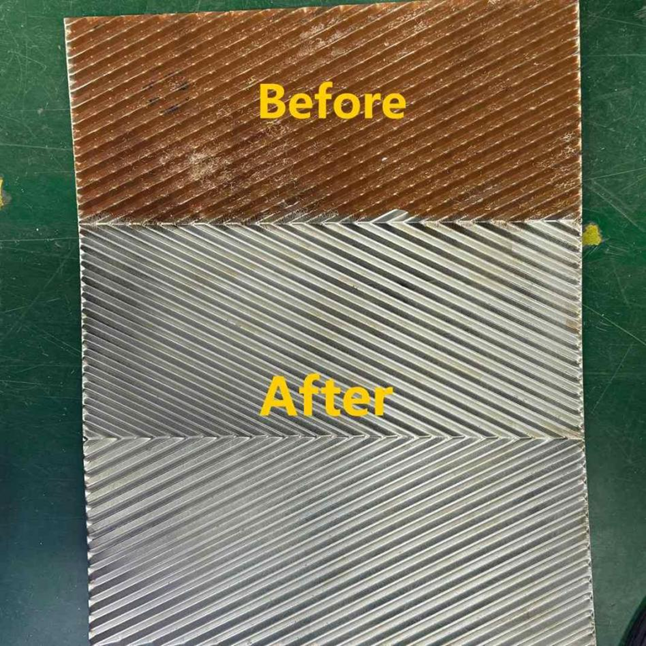

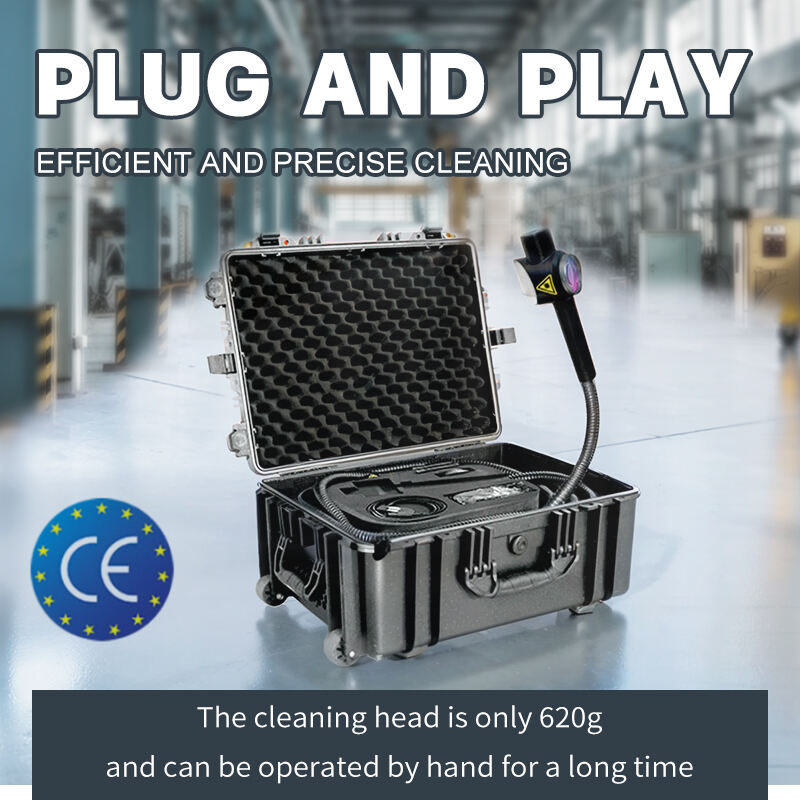

The compact laser marking machine represents a cutting-edge solution in industrial marking technology, combining precision engineering with space-efficient design. This versatile system utilizes advanced laser technology to create permanent, high-quality marks on various materials, including metals, plastics, and ceramics. The machine features a compact footprint that makes it ideal for small to medium-sized manufacturing facilities while maintaining industrial-grade performance capabilities. Its state-of-the-art fiber laser source delivers exceptional marking quality with minimal heat affected zones, ensuring material integrity. The system incorporates user-friendly software interface that enables operators to easily program and control marking parameters, patterns, and depths. With adjustable power settings ranging from 20W to 50W, the machine offers flexibility in marking intensity to accommodate different material properties. The integrated cooling system ensures stable operation d

Get A Quote