Factories need to clean surfaces well. This step matters for making things, fixing them, and restoring old items. Old ways of cleaning—like sandblasting, using chemicals, or scrubbing with machines—have big problems. They make a lot of waste. They can hurt the things being cleaned. They can be dangerous. And they cost a lot to run.

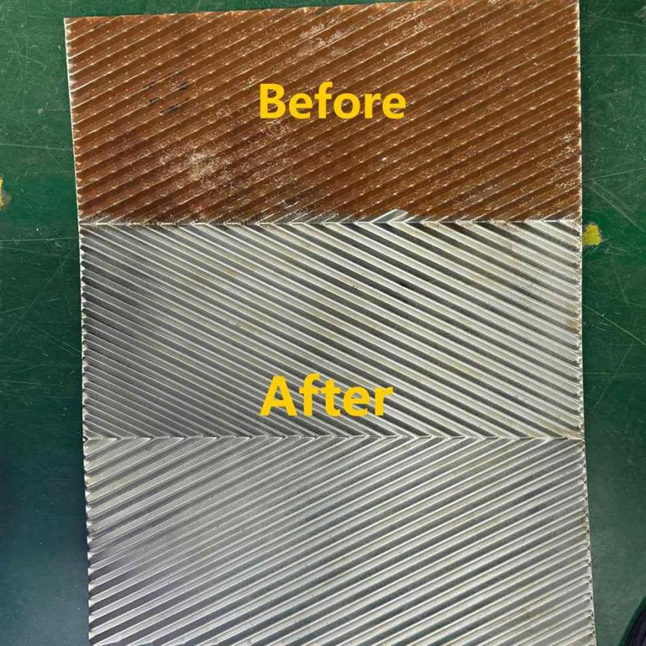

Laser cleaning machines are different. They use strong laser light to take off rust, paint, oil, or dirt from surfaces. These machines are changing how factories work. Let’s look at why they are so good.

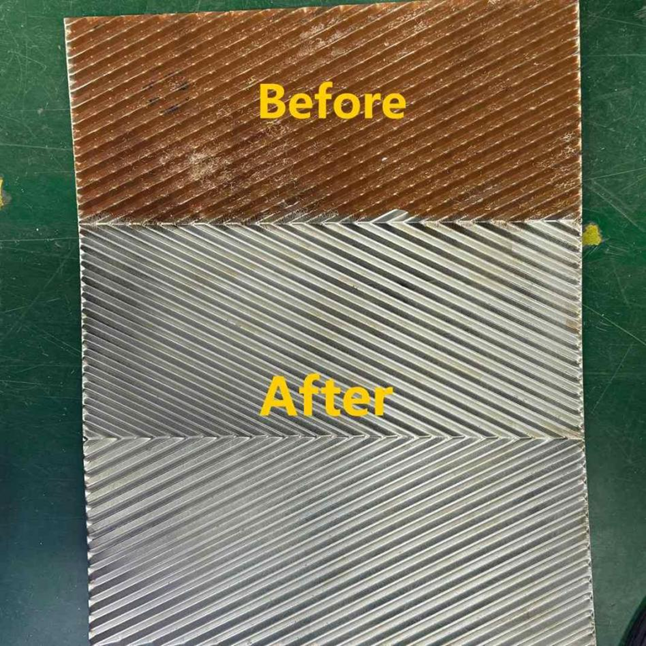

This is one of the best things about laser cleaning machines. They can take off dirt with great accuracy. They do not damage the thing under the dirt.

Old methods like sandblasting or wire brushes rub hard. This can scratch surfaces, make them thinner, or bend them. This is bad for thin materials—like aluminum, plastic mixes, or old metal parts. Fixing this damage costs money. It eats into the factory’s budget.

Laser cleaning machines work in a different way. They use focused laser energy to shake loose or vaporize dirt. They do not touch the surface. The laser energy mostly gets taken in by the dirt (like paint or rust). But it bounces off the base material. That is because the base material soaks up less laser energy.

Workers can set the laser’s power, how long the light pulses, and how fast it moves. This matches how thick the dirt is and what the base material is.

For example, in aerospace factories, laser cleaning machines can take paint off turbine blades. They do this without changing how strong the blades are. Sandblasting can never be this careful.

In fixing old cars, laser machines take rust off the car frames. They do not make the metal weaker. The part stays as strong as it was.

These machines are also good for cleaning tricky shapes. Think of gears, bolts, or molds with small cracks. The laser’s thin beam can get into spots that brushes or chemicals can’t reach. This means the surface gets fully clean, no need to scrub by hand.

Old cleaning methods harm the environment. Using chemicals means toxic liquids. These can pollute water and soil. Getting rid of them costs a lot. Factories have to follow rules, like the EPA’s Resource Conservation and Recovery Act, when throwing them away.

Sandblasting is bad too. It makes a lot of waste—like bits of sand. This fills up landfills. It can also hurt workers’ lungs.

Laser cleaning machines are much better for the environment. They make almost no toxic waste. They do not make chemical goop or dirty air (if used with a good filter). The main thing they make is vapor from the dirt. This vapor is caught and filtered. So there is almost no waste left.

This fits with efforts to keep the planet healthy. It helps factories have a smaller carbon footprint. It also helps them meet green rules, like ISO 14001.

Worker safety is another big plus. Old chemical cleaning uses poisons. Workers can get skin problems, breathing issues, or long-term sickness from these.

Laser cleaning machines need very little protective gear. Workers just need safety glasses (to block the laser) and ear plugs (for strong machines). This means fewer accidents at work.

This not only keeps workers healthy. It also saves factories money. They pay less for insurance. And they spend less on following safety rules.

Time is important in factories. Laser cleaning machines are faster and more efficient than old methods.

Sandblasting takes a lot of time to set up. Workers have to cover areas they don’t want to clean. They have to get the sand ready. And then they have to clean up afterward.

Chemical cleaning is slow too. Parts have to soak for hours. Then they need to be rinsed and dried. This slows down the whole production line.

Laser cleaning machines are ready to use in minutes. There’s no messy setup or cleanup. You turn the machine on, set the laser settings, and start cleaning.

The laser light works quickly. It can take off dirt from a big area in one pass. For example, a laser machine can clean rust from a 1-meter-square steel plate in less than 2 minutes. Sandblasting would take 15 minutes or more for the same job.

Laser machines can also work with robots or conveyor belts. This makes them even faster. In car factories, for example, robot laser cleaners can clean more than 50 engine parts in an hour. They fit right into the assembly line. They don’t slow things down. This means factories can make more things and meet their deadlines.

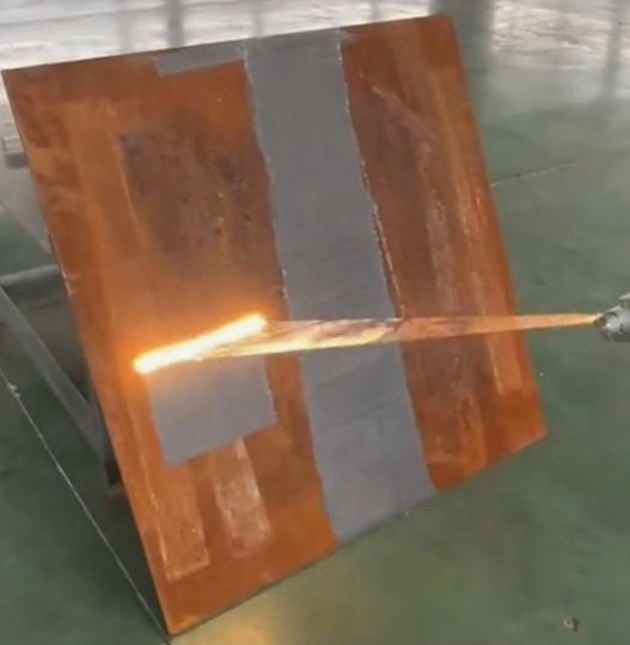

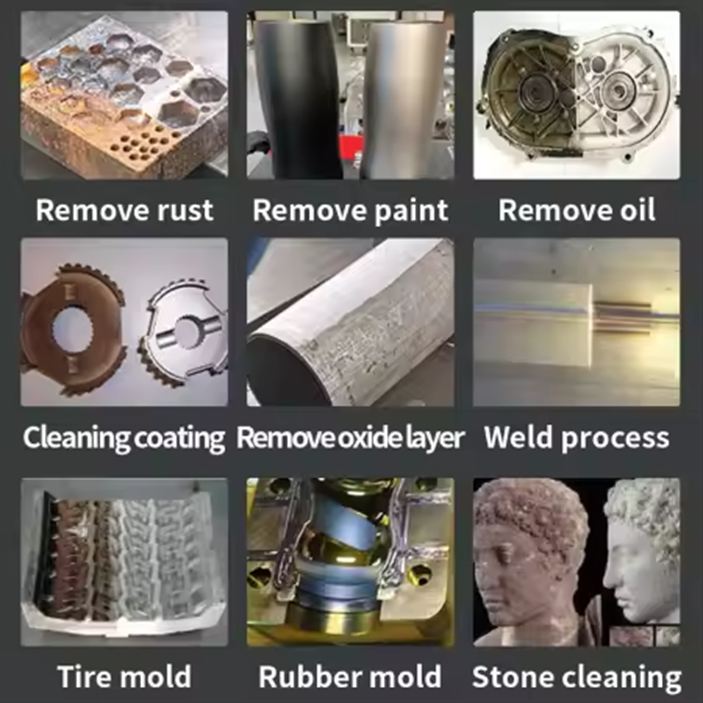

Laser cleaning machines are not stuck to one type of dirt or material. They can be used for many factory jobs.

They can take rust off steel, paint off aluminum, oil off machines, or oxides off circuit boards.

For metals: They work on carbon steel, stainless steel, copper, and titanium. They take off rust, scale, and old coatings. They don’t hurt the metal’s structure. This is important in aerospace. Turbine parts must be totally clean to work safely.

For non-metals: They can clean plastics, mixes of materials, even concrete or stone. In making electronics, for example, they take off leftover glue from circuit boards. They don’t damage the delicate parts.

For old artifacts: Museums and repair shops use them too. They gently take dirt, grime, or old coatings off antique metal, paintings, or statues. This brings the items back to their original look.

Because they can do so many things, factories don’t need lots of different cleaning tools. This saves money on equipment. It also saves space for storage. One laser machine can replace sandblasters, chemical tanks, and wire brushes. This makes the factory’s work easier.

Laser cleaning machines cost more to buy at first than old tools. But over time, they save a lot of money.

Materials: Sand, grit, and chemicals need to be replaced all the time. A medium-sized factory might spend $50,000 or more a year just on sand for sandblasting.

Waste removal: Dangerous waste from chemicals or sandblasting needs special disposal. This costs thousands of dollars in fees.

Labor: Old cleaning methods need many workers. They have to run the machines and clean up. A laser machine can be run by just one worker. This cuts down on labor costs.

Fixing mistakes: Sandblasting or chemicals often damage parts. These parts need to be fixed or replaced. Laser machines are accurate. They don’t hurt the base material. This means fewer costs for fixes.

Over time, these savings add up. A study from the Laser Institute of America says factories that use laser cleaning get their money back in 18 to 36 months. After that, they save 30% to 50% every year compared to old methods.

Yes. By changing the laser’s power and how fast it moves, they can take off thick dirt in a few passes. For example, rust up to 0.5mm thick can be removed in 2 or 3 passes. This works for heavy cleaning jobs.

Many models are made for outside or rough places. Portable laser machines with weatherproof cases and batteries are used for field work. They can clean rust from bridges, pipes, or construction machines.

Dry ice blasting works, but it makes waste (dry ice bits) and can damage delicate surfaces. Laser cleaning is more accurate. It makes no waste and is safer for workers. But it costs more to buy at first.

Basic training (1 or 2 days) is enough. Workers learn about laser safety, changing settings, and keeping the machine in good shape. They learn how to match the laser settings to the dirt and material. This makes sure the cleaning works well. Stronger lasers might need a certificate, but this is easier than learning to handle chemicals.

Yes. Most industrial laser cleaning machines work with robots, conveyors, and vision systems. They fit smoothly into how factories make things. This automation means fewer mistakes by workers. It also means more things get made.