In factories, clear marking is more than just a step—it’s a big deal. It helps check if products are good. It helps track where products go. It even makes customers trust your brand more. A laser marking machine is perfect for this job. It makes marks that stay forever, sharp and easy to read, on metal parts, plastic pieces, and more.

But there are so many laser marking machines out there. Each one works differently. Some are fast. Some make tiny marks. Some cost more than others. To pick the right one for your factory, you need to think about what you’re marking, how you want the marks to look, and how many products you make. Let’s go through it step by step.

The first thing to figure out is: what materials do you need to mark? Different lasers work best with different materials. Using the wrong laser can make marks blurry, damage your products, or slow down your work.

If you work with metals, a fiber laser marking machine is the way to go. Here’s why: it uses a super-strong beam with a short wavelength (about 1.06μm). Metals soak up this beam really well. When the laser hits the metal, it makes a mark that’s crisp and lasts a long time. And it doesn’t hurt the metal—no bending, no discoloration, just a clean mark.

Car factories use fiber lasers a lot. They mark serial numbers on engine parts. These numbers stay clear even after the engine has been running for years, covered in oil and heat. This way, if something goes wrong, workers can track down which part it is, right back to when it was made.

Aerospace factories love them too. They mark tiny numbers on turbine blades—parts that spin super fast and get really hot. The marks don’t fade or wear off, even when the blades are working in extreme conditions. That’s how important fiber lasers are for metals.

For things that aren’t metal—like plastics, wood, glass, or leather—a CO₂ laser marking machine is better. It has a longer wavelength (10.6μm) that’s just right for these materials. Instead of cutting into the material, it gently burns off the top layer, leaving a mark that’s clean and sharp.

Packaging plants use CO₂ lasers all the time. They mark expiration dates on plastic bottles. Imagine a line that fills 10,000 bottles an hour—this laser keeps up, zapping the date on each bottle in a split second. No smudges, no mistakes.

Furniture makers use them too. They etch logos into wooden tables or leather chairs. The laser doesn’t scratch the wood or ruin the softness of the leather—it just leaves a neat mark that makes the product look more professional. Even glass factories use CO₂ lasers to add patterns or warnings to glass panels. The laser is gentle enough that it won’t crack the glass, which is super important.

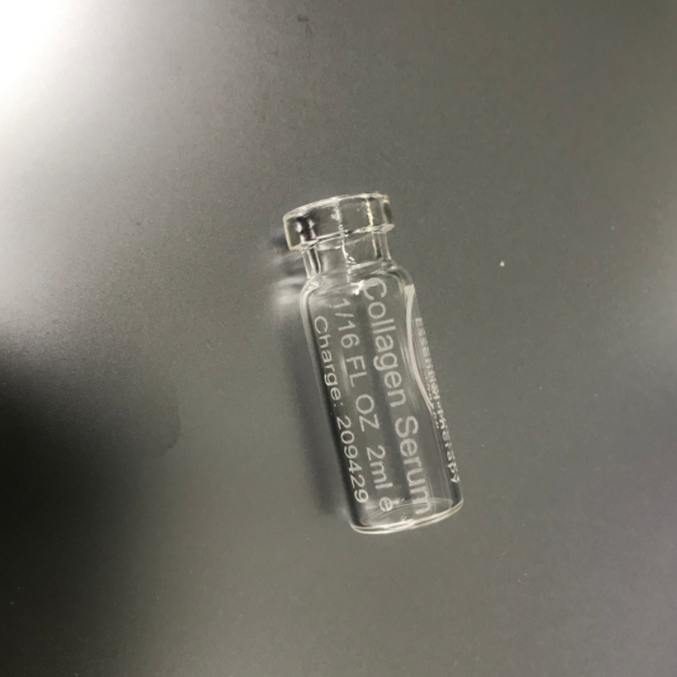

Some materials are tricky. Ceramics, for example, or composites that break if they get too hot. For these, you need a UV laser marking machine. It has a super-short wavelength (355nm) that works like “cold marking”—it touches the surface without making much heat. This way, the material stays safe.

Medical factories rely on UV lasers a lot. They mark tiny serial numbers on plastic syringes or metal surgical tools. The marks are so small you might need a microscope to read them, but they’re clear. And because the laser doesn’t make much heat, the tools stay sterile and don’t get damaged—critical for keeping patients safe.

Not all marks are the same. Some are simple. Some are tiny. Some need to last through rain, heat, or rough use. Your laser marking machine should be able to make the marks you need, exactly how you need them.

If you just need to add words, barcodes, or simple logos, a standard laser marking machine is enough. Look for one with a resolution of 300–600 dpi (dots per inch). These machines aren’t too expensive, and they’re easy for workers to use.

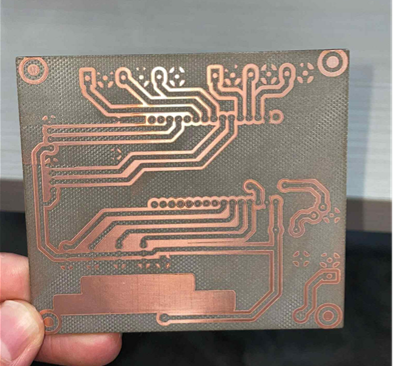

Electronics factories use these a lot. They mark part numbers on circuit boards. The marks don’t need to be fancy—just clear enough that a scanner can read them quickly. Food factories use them too, stamping batch codes on cardboard boxes. Here, speed matters more than making the mark look perfect.

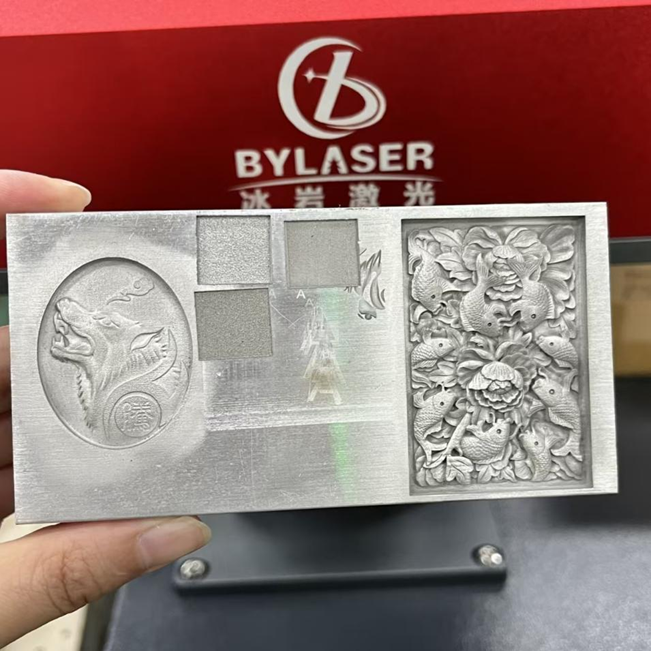

If you need marks with lots of details—like tiny words on microchips, pretty patterns on jewelry, or 2D codes that store lots of data—you need a high-resolution laser marking machine. Look for one with 1000+ dpi. These machines can make marks as small as 0.01mm, which is thinner than a human hair.

Jewelry makers love these lasers. They can etch delicate flowers or patterns into gold or silver rings without scratching the metal. The marks are so precise that they make the jewelry look more valuable. Semiconductor factories use them too, marking tiny QR codes on microchips. These codes hold info like when the chip was made and which factory made it. You need a special scanner to read them, but the laser makes sure every little line is clear.

Some marks need to stick around for years, even if they’re exposed to water, heat, or rubbing. For example, marks on engine parts that get hot, or on steel beams outside that get rained on. For these, the laser needs to mark deep into the material.

Fiber lasers are great for this. You can turn up their power, and they’ll cut deeper into the metal. The marks won’t wear off, even after years of use. Construction companies do this, marking steel beams with how much weight they can hold. Paint or welding won’t cover these deep marks, which is important for safety.

Factories can’t slow down—they need to make lots of products quickly. Your laser marking machine has to keep up with how many products you make each day.

If you make a few products at a time—like custom metal parts for local shops, or personalized gifts—a desktop laser marking machine is perfect. It’s small, so it won’t take up much space in your factory. It’s easy to set up: plug it in, load your part, press a button, and it’s done. You don’t need any fancy machines to move parts around.

Small metal shops use these to mark custom knives with people’s names. Small furniture makers use them too, adding customer names to wooden plaques. These machines don’t need to be super fast—they just need to be reliable, so you can trust them to make good marks every time.

If you make hundreds or thousands of products a day—like car parts, phone cases, or bottles—you need an industrial-grade laser marking machine. It has to be fast, with scanning speeds up to 10,000 mm/s. It also needs automation features, like conveyor belts to move parts through, or robot arms to load and unload parts without workers touching them.

Car factories are a great example. Their assembly lines move super fast—maybe 60 engines an hour. A high-speed fiber laser marking machine, attached to a robot arm, can mark each engine’s serial number in less than 2 seconds. It keeps up with the line, so nothing gets backed up. Shipping warehouses use these too, marking barcodes on metal containers as they zip down conveyor belts. This way, every container can be tracked from the factory to the customer’s door.

A laser marking machine is only helpful if your workers can use it without struggling. The software and controls should be simple, even for people who aren’t good with technology.

Good software lets you load designs in seconds. You should be able to use files from programs like Adobe Illustrator or AutoCAD—no special training needed. Changing settings like speed or power should be easy, with sliders or buttons, not confusing code.

Many machines also have “variable data” features. This means you can set the laser to mark different numbers or dates automatically. For example, a juice factory can set it to mark “Best Before: 06/2026” on one bottle, then “07/2026” on the next, without anyone typing each date. This saves tons of time.

Touchscreen controls are a must. Workers should be able to pick a design, change a few settings, and start marking with just a few taps. Some machines even have preset modes: “Mark Metal Fast,” “Mark Plastic Clearly”—so new workers can start using them right away, without lots of training.

Lasers are powerful—they can hurt people if not used carefully. Your laser marking machine must have safety features to keep workers safe, and it must follow all the rules for your industry.

Interlocked enclosures: If the door or cover is open, the laser stops working. This way, no one gets hit by the laser beam.

Emergency stop buttons: Big, bright buttons that shut the machine down right away if something goes wrong.

Clear labels: Most industrial lasers are Class IV, which means they’re strong. They should have labels warning workers, and everyone using the machine should wear special glasses to protect their eyes from the laser.

Different industries have different rules for marking. For example:

Medical tools need marks that follow ISO 13485. This way, doctors can track where the tool was made, when, and if it passed safety tests—critical if there’s a problem.

Aerospace parts need marks that follow AS9100. These marks have to survive extreme heat, cold, and pressure—like what parts go through in a plane engine.

Food packaging needs marks that are safe to be near food. CO₂ lasers are great for this because they don’t use chemicals—no risk of toxic stuff getting on the food.

Some machines let you switch between fiber lasers (for metals) and CO₂ lasers (for non-metals), but this costs more and takes time to set up. For most factories, it’s easier to have two separate machines—one for metals, one for non-metals.

Fiber lasers: Not much. Clean the lens every few weeks, and replace the filter once a year.

CO₂ lasers: Need a bit more care. Check the laser tube every 6 months to make sure it’s working.

UV lasers: Have delicate parts. It’s best to have a technician check them once a year.

With good care, a laser marking machine can last 10–15 years. The laser source (the most expensive part) usually lasts 5–10 years. Fiber laser sources often last 100,000+ hours—that’s like running 24 hours a day, 7 days a week, for 11 years.

Basic use takes a few hours to learn. For fancier features, like automation or making super detailed marks, plan a day of training. Most companies that sell the machines will train your workers for free when you buy one.