Rust is a big problem for metal. That reddish-brown stuff has bothered industries for hundreds of years. It makes metal weak. It ruins how metal looks. It makes fixing things more expensive.

People have tried many ways to get rid of rust. They used sandblasting. They used chemicals. They used wire brushes. But each way has issues. Some are slow. Some hurt the metal itself. Others are bad for the environment.

Then laser rust cleaning machines came. They changed how we remove rust. They are precise. They are safe. They can do many things. Industries now want cleaner, faster, and more earth-friendly ways. These machines have become the top choice. Let’s see why they are the best tool for rust removal.

Laser rust cleaning machines have a big plus. They take off rust without hurting the metal underneath.

Old ways like sandblasting or wire brushing work by scraping. They remove rust. But they often scrape off part of the metal too. This can make metal thinner. It can make structures weak. It can even change the size of parts that need to be exact. In fields like aerospace, even 0.1mm of change can make a part useless.

Laser rust cleaning machines work differently. They use a strong laser beam. This beam turns rust into gas. It does this at a tiny, molecular level. Rust soaks up the laser’s energy differently than metal. Steel and aluminum are good examples. So the rust gets hot fast. It turns into vapor and disappears. The metal below stays cool. It stays unharmed.

Workers can adjust the laser. They change how strong it is. They change where it focuses. They change how fast it moves. These changes match how thick the rust is. They match what kind of metal is being cleaned. This means rust comes off exactly right every time.

This precision helps with delicate or expensive items. For example, when fixing old cars, a laser can clean rust from vintage parts. It won’t scratch the original metal. It won’t damage rubber gaskets nearby.

In factories, it cleans rust from precise molds or engine parts. It doesn’t change their size. This means less need to redo work. That saves money. Old ways can’t do this.

Time is money in factories. Laser rust cleaning machines are faster than old ways.

Sandblasting takes time to set up. You have to get abrasive materials ready. You have to cover areas you don’t want to blast. Workers also have to go slow. They don’t want to damage the metal.

Chemical treatments are even slower. You have to soak the metal for hours. Then you have to rinse it. Then you have to dry it.

Laser rust cleaning machines are ready in minutes. No messy abrasives. No dangerous chemicals. Just turn them on. Set them up. Start cleaning.

They can cover big areas quickly. A single pass over a rusty steel plate can remove surface rust in seconds. Some laser machines are on robot arms. They can clean big things like bridges. They can clean complicated shapes. They can clean several square meters every hour.

This speed means more work gets done. A study compared rust removal ways. It found a laser machine finished a job in a third of the time sandblasting took. It also needed half as many worker hours.

For industries like shipbuilding or construction, stopping work costs money. This speed gets equipment back in use faster.

Old rust removal ways are bad for the environment. They are bad for people.

Chemical treatments use acids or solvents. These are poisonous. If they spill, they can pollute soil and water. If they aren’t thrown away right, they can do the same.

Sandblasting makes a lot of dust. This dust includes silica or aluminum oxide. If workers breathe it, they can get sick. It can cause lung diseases like silicosis.

Both ways need expensive waste disposal. Workers also need lots of safety gear. They need masks. They need gloves that resist chemicals. This keeps them safe.

Laser rust cleaning machines fix these problems. They are the safest option. They are the most earth-friendly option.

They don’t make chemical messes. They don’t make dangerous dust. They don’t create waste. Rust turns into harmless gas. Often, a HEPA filter cleans this gas. The air stays clean.

This means less need to manage waste. It means fewer fines for breaking environmental laws. The EPA’s Clean Water Act is one example.

For workers, this is much better. They only need basic safety gear. They need glasses to block the laser light. They might need ear protection if using machines with robots. They don’t breathe toxic fumes or dust.

This makes workplaces safer. It cuts insurance costs. It reduces long-term health problems. For companies that care about being green or following safety rules, laser rust cleaning machines are an easy choice.

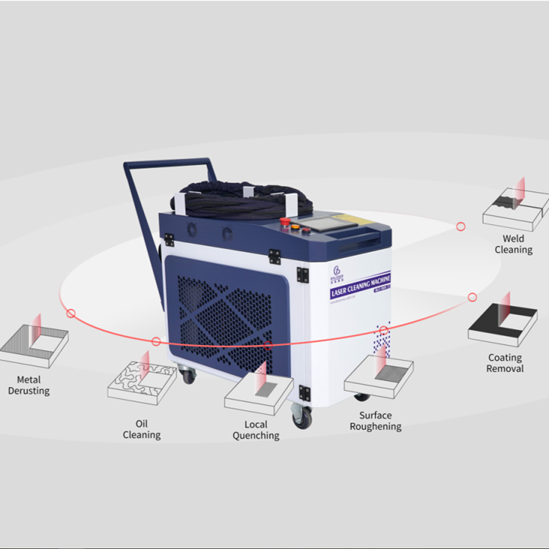

Laser rust cleaning machines aren’t just for rust. They are good at many surface cleaning jobs. This makes them a smart buy.

They can remove paint. They can remove oil. They can remove grease. They can remove oxide layers. They can even remove graffiti. They work on metal. They work on stone. They work on concrete.

So you don’t need lots of different tools. This saves space. It reduces equipment costs.

In aerospace, for example, the same laser machine can remove rust from airplane parts. It can also take off old paint from the plane’s body. This gets the surface ready for new paint.

In factories, it cleans oil and dirt from metal parts after they’re made. This helps welding or painting stick better.

Even in historical preservation, it gently removes dirt and rust from old metal artifacts. It doesn’t damage delicate surfaces. No abrasive or chemical way can do that.

These machines work on all kinds of metal. They work on ferrous metals like steel and iron. They work on non-ferrous metals like aluminum and copper. They even work on precious metals like gold and silver.

This makes them useful in many industries. Car making, shipbuilding, energy, and art restoration all use them.

Laser rust cleaning machines cost more to buy than sandblasting tools or chemicals. But they save money over time.

Old ways have ongoing costs. You have to keep buying abrasives or chemicals. You have to pay to throw away waste. Workers need more time to do the job. That costs more.

Laser rust cleaning machines have very few ongoing costs. They use electricity. This is cheaper than buying and throwing away abrasives or chemicals. They don’t have parts that need constant replacing. Maintenance is simple. Sometimes you clean the lens. Sometimes you change a filter.

These savings add up. A medium-sized factory said it got back the money it spent on the laser machine in 18 months. It saved on labor. It saved on materials. It saved on waste disposal.

Also, the laser’s precision means less rework. Sandblasting can damage parts. Chemicals can leave residue. Fixing these problems costs time and money. Lasers rarely make these mistakes. So long-term costs stay low.

It’s not likely, but it can happen. If the power is too high on thin metal, it could cause damage. But new machines have safety features. They let you adjust power. They have settings for different metals. This stops mistakes.

Most machines can remove rust up to 0.5mm thick in one pass. Thicker rust may need a few passes. But even then, it’s faster than sandblasting for heavy rust.

Yes. There are portable models. They are made to handle rain or humidity, as long as it’s safe. They’re great for outdoor things like bridges or tanks.

Workers usually need a day of training. They learn safety rules. They learn how to adjust settings. They learn basic maintenance. Some places require a certificate. But it’s easier than training for handling chemicals.

With good care, a quality machine can last 10–15 years. The laser itself can work for 100,000+ hours. So it will work reliably for a long time.