As industrial manufacturing advances, surface cleaning and precision treatment have become increasingly important in modern production. Pulse laser cleaning machines have emerged as a revolutionary solution, offering high precision, non-contact operation, and environmentally friendly cleaning. Modern laser cleaning machines effectively remove rust, oxidation layers, paint, and other contaminants from metal and non-metal surfaces while maintaining the integrity of the substrate. This technology not only improves production efficiency but also reduces environmental impact, meeting the high standards of industrial surface treatment.

The heart of every pulse laser cleaning machine lies in its laser source. Industrial-grade machines typically use fiber lasers or YAG lasers to generate high-intensity light pulses. The power of these machines ranges from tens to over a thousand watts, and pulse frequency and duration can be adjusted according to the material type and contamination thickness. By precisely controlling pulse parameters, a pulse laser cleaning machine can efficiently remove rust and coatings while preventing thermal damage to the base material.

Pulse laser cleaning machines feature advanced optical systems, including mirrors, lenses, and scanning modules, to ensure uniform laser delivery across the surface. Modern machines often include dynamic focus control, automatically adjusting the focal point for uneven surfaces. This feature guarantees consistent cleaning performance on complex geometries and irregular surfaces, enhancing operational efficiency in industrial applications.

Sophisticated software interfaces are essential for modern pulse laser cleaning machines. These systems provide real-time monitoring and allow operators to create, save, and modify cleaning programs for different materials and contamination types. Safety protocols and emergency shutdown features are integrated into the software to ensure operator protection. Many pulse laser cleaning machines can be integrated into automated production lines, allowing seamless connection with manufacturing execution systems (MES) for data collection, process optimization, and precise cleaning control.

The power output of a pulse laser cleaning machine directly affects its cleaning capacity and processing speed. High-power lasers can quickly remove thick rust or multi-layer coatings, while lower-power lasers are suitable for delicate cleaning tasks. Industrial applications require careful consideration of peak power versus average power. High peak power enhances the removal of stubborn contaminants, whereas average power determines the overall processing speed. Properly balancing these parameters ensures effective cleaning while protecting the substrate.

Beam quality is critical for cleaning precision and efficiency. High-quality laser beams distribute energy evenly, ensuring consistent cleaning results. Pulse laser cleaning machines often provide adjustable focal lengths and beam shaping functions, allowing customization for different surface geometries and contamination types. Advanced focus control reduces operator intervention and enhances automation, particularly when cleaning large or irregular surfaces.

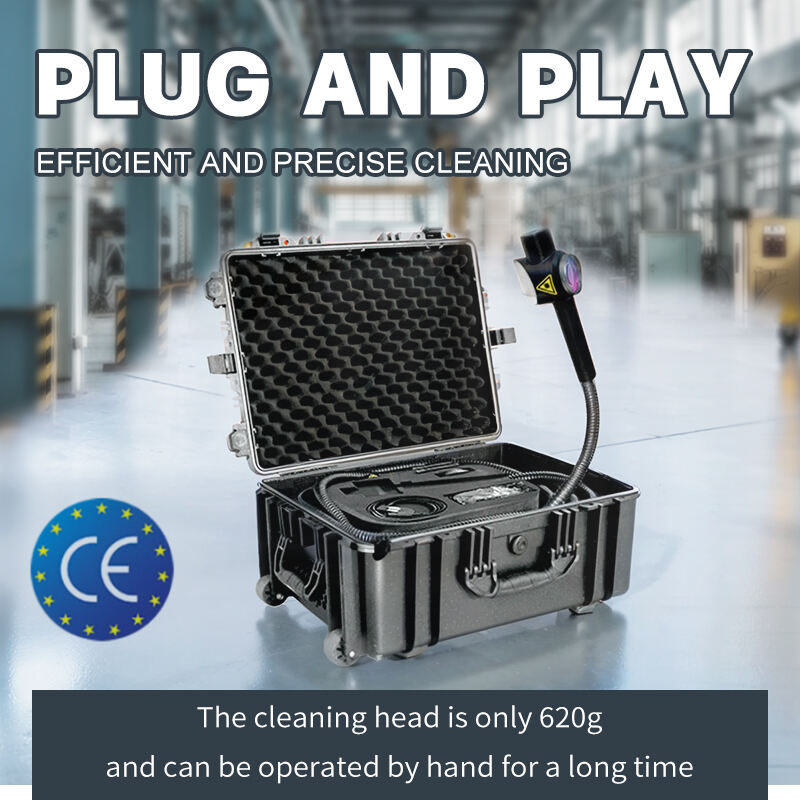

Industrial laser cleaning machines typically use air or water cooling systems to maintain stable operation. High-power machines often require water cooling to prevent overheating, while portable models use air cooling for flexibility and mobility. The machine configuration should be chosen based on the production environment and cleaning requirements to ensure optimal efficiency and safety.

Pulse laser cleaning machines excel at treating metal surfaces, effectively removing rust, oxidation layers, paint, and welding residues from steel, aluminum, copper, and other metals. Unlike traditional mechanical or chemical methods, pulse laser cleaning is non-contact, non-abrasive, and environmentally friendly, preserving the structural integrity of the metal and minimizing processing risks.

Industrial molds are a common application for pulse laser cleaning machines. Injection molds, die-casting molds, and stamping molds can have residues or oxidation layers removed quickly without the use of chemicals or mechanical abrasives. This approach extends mold life, reduces downtime, and lowers maintenance costs.

Pulse laser cleaning machines are widely used in aerospace, electronics, and semiconductor manufacturing. Turbine blades, electronic soldering points, and sensitive components can be cleaned without thermal damage, ensuring high-precision surface preparation. The technology can also clean irregular or curved surfaces, meeting strict industrial standards for precision and repeatability.

Pulse laser cleaning machines are suitable for artifact restoration and sensitive material cleaning. For ancient metal artifacts, sculptures, or delicate artworks, laser cleaning can remove contaminants accurately without damaging the original surface, providing an environmentally friendly and highly precise restoration solution.

Modular design in pulse laser cleaning machines facilitates maintenance of key components such as the laser source, optics, and scanning system. Regular cleaning of optical parts, inspection of the cooling system, and system diagnostics ensure long-term performance. Choosing a manufacturer with reliable technical support and available spare parts is crucial for continuous production operations.

Proper training is required for safe operation of pulse laser cleaning machines. Operators should use appropriate personal protective equipment, and machines are equipped with safety interlocks, emergency stops, and laser radiation protection systems to prevent accidents. Selecting equipment that complies with safety standards ensures secure operation and minimizes workplace risks.

Although pulse laser cleaning machines require a higher initial investment, they provide significant long-term value. Reduced consumable use, lower waste generation, and minimized labor costs contribute to overall cost savings. Efficient, precise cleaning also reduces defective parts, enhancing production efficiency and maximizing return on investment. Industrial operators can evaluate long-term economic benefits based on cleaning requirements, production volumes, and potential new applications.

Pulse laser cleaning machines require regular cleaning of optical components, inspection of cooling systems, and periodic system diagnostics. Most systems are capable of long continuous operation, with quarterly or annual professional maintenance recommended to ensure optimal performance.

When properly configured with suitable power and pulse parameters, pulse laser cleaning machines can safely clean sensitive materials, including electronic components or cultural artifacts. Pre-programmed cleaning modes help prevent substrate damage.

Pulse laser cleaning machines provide contactless, chemical-free, and environmentally friendly cleaning. They offer precise control, minimize waste, and can be automated for consistent results. Although the initial investment is higher, long-term cost savings and process improvements are substantial.

The required laser power depends on material type, contaminant thickness, and desired cleaning speed. Collaborating with suppliers for application testing helps determine optimal power and pulse settings for specific industrial cleaning tasks.