Modern manufacturing demands precision, efficiency, and versatility in marking and identification processes. The UV laser marking machine has emerged as a groundbreaking solution, transforming how manufacturers approach product identification and traceability. This sophisticated technology harnesses the power of ultraviolet light to create permanent, high-contrast marks on various materials without causing thermal damage or compromising product integrity.

As industries evolve and quality standards become more stringent, the demand for precise marking solutions continues to grow. UV laser marking machine technology offers unprecedented advantages in terms of mark quality, production speed, and material compatibility. From medical devices to electronic components, this innovative marking solution is reshaping manufacturing processes across diverse sectors.

The UV laser marking machine delivers exceptional marking quality through its unique wavelength characteristics. Operating at a shorter wavelength than traditional laser systems, it produces incredibly fine, high-resolution marks with superior contrast. This precision is particularly valuable when marking small components or creating complex patterns that require microscopic detail.

The technology's ability to create cold marks ensures that sensitive materials remain undamaged during the marking process. This cold marking capability makes the UV laser marking machine ideal for temperature-sensitive materials and delicate electronic components where thermal damage must be avoided at all costs.

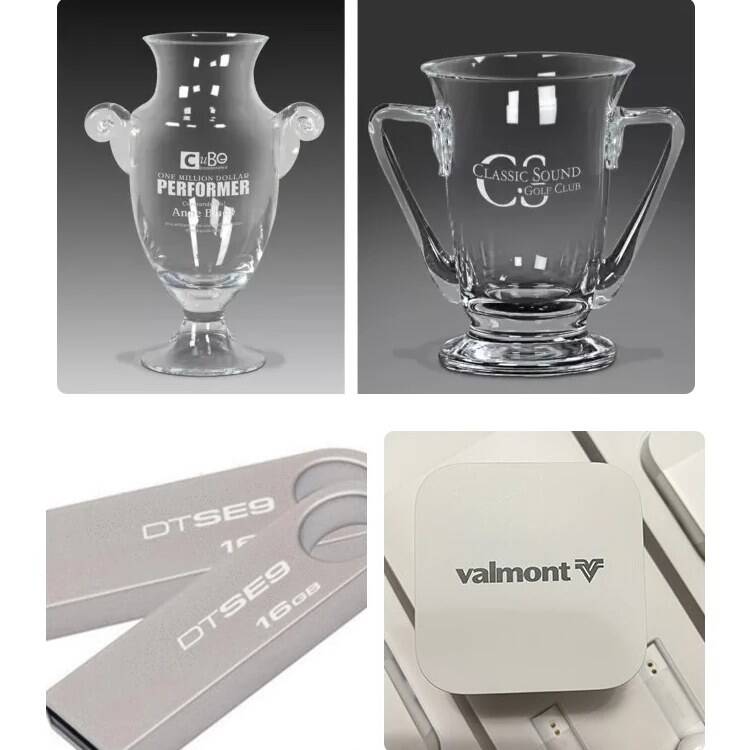

One of the most significant advantages of UV laser marking machine systems is their versatility in handling different materials. The technology excels at marking plastics, ceramics, glass, and various sensitive substrates that prove challenging for conventional marking methods. This broad material compatibility eliminates the need for multiple marking systems in production facilities.

Manufacturers particularly appreciate the UV laser marking machine's ability to process transparent and translucent materials effectively. The unique properties of UV wavelengths allow for precise internal marking of clear materials, creating three-dimensional effects that are impossible with other marking technologies.

While the initial investment in a UV laser marking machine may seem substantial, the long-term cost benefits are significant. The system requires minimal consumables, reduces waste, and operates with low maintenance requirements. These factors contribute to a lower total cost of ownership compared to traditional marking methods.

The high-speed processing capabilities of UV laser marking machine systems also contribute to cost efficiency. Faster marking cycles mean higher throughput, allowing manufacturers to meet demanding production schedules without compromising quality. Additionally, the precision of UV laser marking significantly reduces error rates and material waste.

UV laser marking machine technology aligns perfectly with sustainable manufacturing practices. The process is clean, requiring no inks, solvents, or chemical additives that could harm the environment. This ecological advantage makes it an attractive option for manufacturers committed to reducing their environmental footprint.

The technology also provides enhanced workplace safety compared to traditional marking methods. With no toxic chemicals or hazardous materials involved, operators can work safely and efficiently. The enclosed design of modern UV laser marking machine systems includes advanced safety features that protect workers from UV exposure.

In the medical industry, UV laser marking machine technology has become indispensable for creating permanent, sterile marks on surgical instruments and implants. The ability to produce high-contrast, durable marks without compromising device integrity or biocompatibility makes this technology particularly valuable for medical manufacturers.

The precision of UV laser marking ensures compliance with strict regulatory requirements for medical device identification. Manufacturers can create detailed tracking codes, serial numbers, and other essential information that remains legible throughout the product's lifecycle, even after repeated sterilization processes.

The electronics industry benefits significantly from UV laser marking machine capabilities, especially in marking sensitive components and circuit boards. The cold marking process prevents thermal damage to delicate electronic parts while ensuring permanent identification marks that withstand assembly and testing procedures.

Semiconductor manufacturers particularly value the ability to create microscopic marks on various substrate materials. The UV laser marking machine's precise beam control allows for marking at the micron level, essential for component tracking and quality control in semiconductor production.

The future of UV laser marking machine technology points toward enhanced integration with Industry 4.0 principles. Manufacturers can expect improved connectivity options, advanced data collection capabilities, and seamless integration with manufacturing execution systems (MES). These developments will further streamline production processes and enhance traceability.

Artificial intelligence and machine learning integration are also on the horizon, promising to optimize marking parameters automatically based on material characteristics and production requirements. This advancement will make UV laser marking systems even more efficient and user-friendly.

As technology continues to evolve, new applications for UV laser marking machine systems emerge regularly. From advanced packaging solutions to innovative security marking features, manufacturers are discovering novel ways to leverage this versatile technology. The development of new materials and industries creates additional opportunities for UV laser marking applications.

Research and development efforts focus on expanding the capabilities of UV laser marking machine technology, including faster processing speeds, enhanced mark quality, and broader material compatibility. These advancements will continue to solidify the technology's position as a crucial tool in modern manufacturing.

UV laser marking machines excel at marking a wide range of materials, including plastics, glass, ceramics, and sensitive electronic components. They are particularly effective on transparent and translucent materials, as well as materials that are sensitive to thermal damage.

Marks created by UV laser marking machines are permanent and highly durable. They resist fading, weathering, and chemical exposure, making them ideal for applications requiring long-term traceability and identification.

UV laser marking machines require minimal maintenance compared to traditional marking systems. Regular cleaning of optical components, periodic laser source checks, and standard system diagnostics are typically sufficient to maintain optimal performance. Most systems are designed for continuous operation in industrial environments.