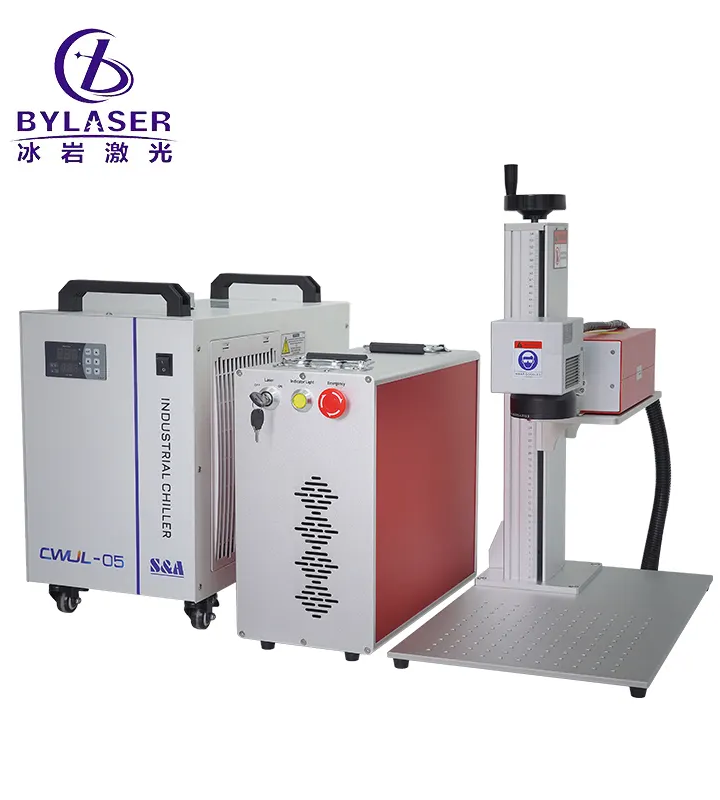

Integrate BY Laser’s laser marking machine into fully automated robotic cells for seamless part identification. With up to 100 W fiber-laser power, real-time path correction, and Ethernet/IP connectivity, it delivers consistent marks on complex geometries. Manufactured under ISO 9001, each unit features safety light curtains, PLC interfacing, and a comprehensive SDK for software integration. B2B clients receive turnkey robotic integration support, on-site commissioning, and operator certification—accelerating high-volume marking in automotive, aerospace, and electronics assembly lines.

Sustainability meets performance with BY Laser’s energy-efficient laser marking machines. Our systems consume less power while maintaining excellent marking quality. BY Laser helps B2B partners reduce their environmental footprint without compromising operational goals, making our solutions both responsible and productive.

Automation enhances efficiency, but marking operations often remain manual. BY Laser’s laser marking machines offer seamless PLC and robot-arm interfacing, complete with safety light curtains and synchronized triggers. Customizable CAD/CAM nesting ensures minimal downtime when switching designs. B2B manufacturers gain turnkey packages—including hardware, software, and operator training—enabling unmanned, high-throughput marking cells. This integration reduces labor costs, increases consistency, and supports just-in-time manufacturing demands.

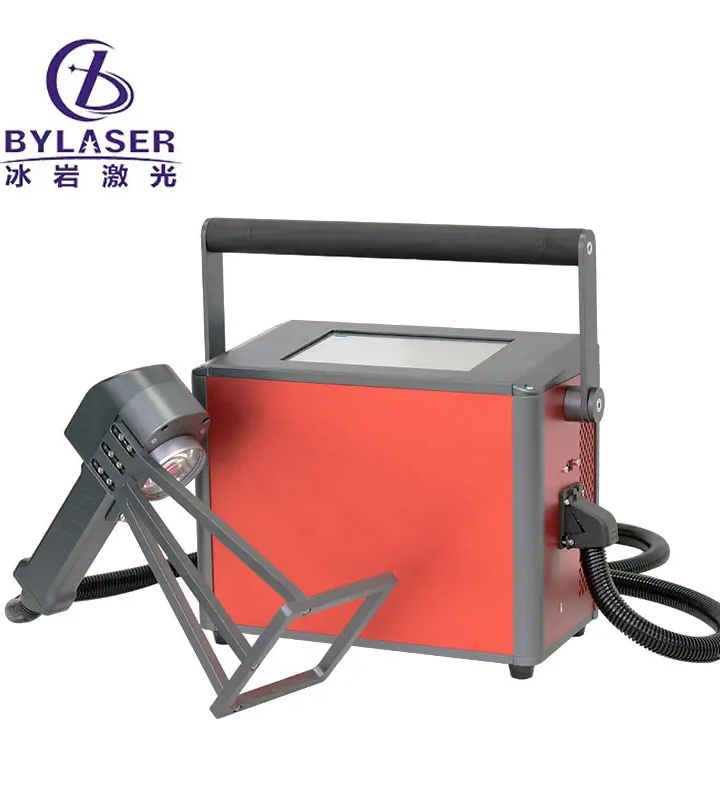

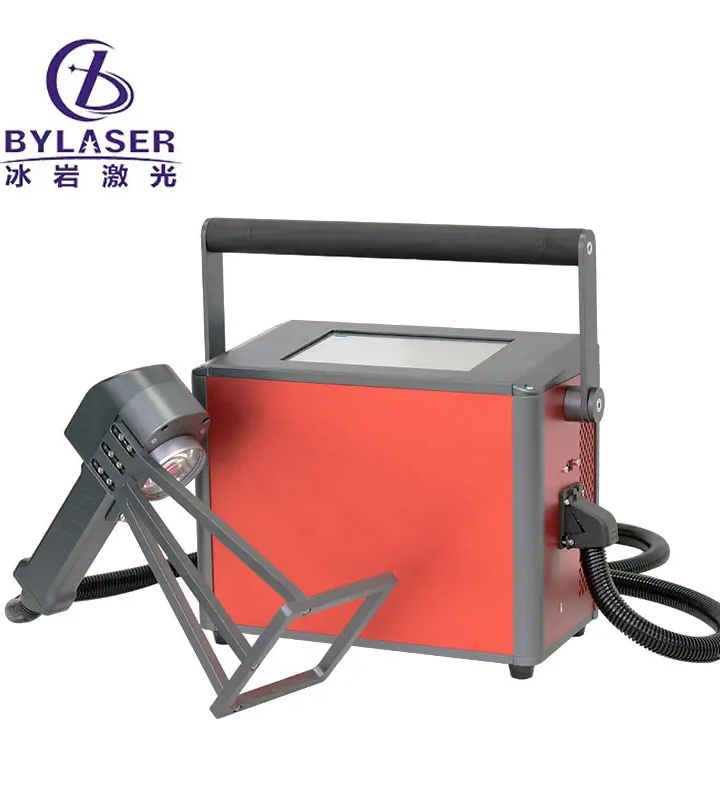

BY Laser delivers high-performance laser marking machines tailored for industrial-scale operations. Our machines ensure precise, permanent marks on metals, plastics, and more. Designed for automation integration, BY Laser systems reduce human error and enhance production output. Trusted by manufacturers worldwide, we support diverse applications with long-term operational stability and reliable marking results.

Reliable marking performance depends on proactive service. BY Laser offers tiered support contracts—including remote diagnostics, firmware updates, and scheduled preventive maintenance—for its laser marking machines. Regional spare-parts stocking—galvo modules, laser diodes, fume filters—ensures rapid replacement. A dedicated support portal provides 24/7 ticketing, video troubleshooting, and training resources. B2B clients gain predictable maintenance budgets, reduced downtime, and ongoing access to technical expertise—preserving marking system uptime.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber (1,064 nm), UV (355 nm), CO₂ (10,600 nm), and dual-source configurations for versatile marking.

Compatible substrates include stainless steel, aluminum, plastics, glass, ceramics, and coated surfaces.

Standard interfaces: Ethernet/IP, PROFINET, EtherCAT; optional PLC and vision-system support for automation.

Preventive maintenance every 1,000 hours; replace fume filters and verify beam alignment per usage.

Enclosed marking chambers, safety interlocks, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and specification approval; expedited options available.