BY Laser’s UV laser marking machine uses a 355 nm picosecond laser to produce crisp, low-stress marks on plastics, glass, and coated substrates. With sub-20 µm spot sizes and adjustable pulse durations, it delivers high-contrast graphics without substrate damage. Built to ISO 9001 standards, it features inline process monitoring, temperature-controlled enclosures, and custom fixtures. B2B customers benefit from detailed application testing, contrast-optimization services, and extended maintenance agreements to guarantee long-term marking quality on sensitive materials.

BY Laser understands that every business has unique marking requirements. Our laser marking machines are adaptable to various materials and production volumes. Whether for serial numbers, barcodes, or logos, our systems provide high-resolution markings that meet industry standards. BY Laser offers customizable solutions for clients across manufacturing sectors.

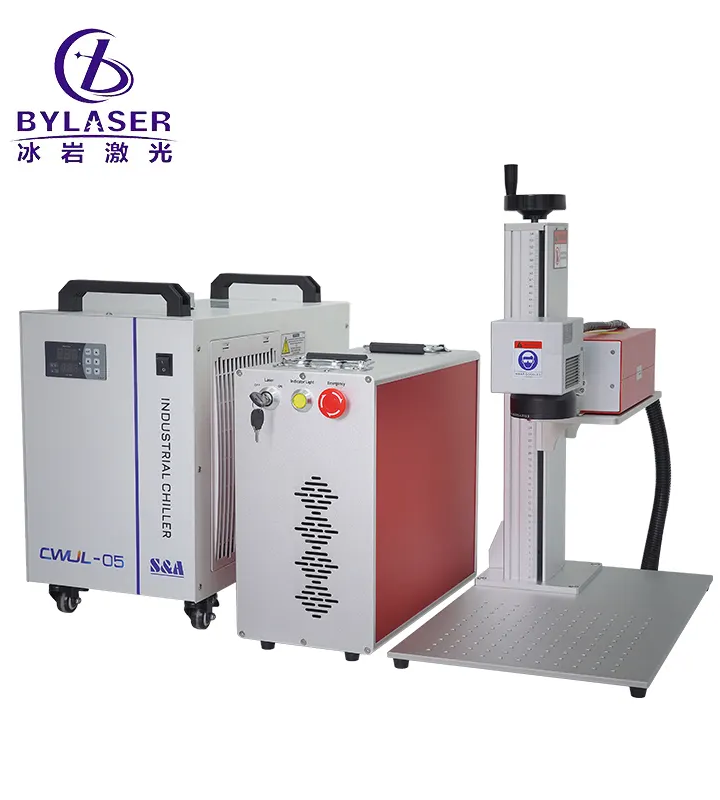

Maximize space and efficiency with BY Laser’s compact laser marking machines. Ideal for integration into tight production lines, our systems are small in size but big on performance. B2B clients benefit from streamlined operation and flexible configurations without sacrificing speed or precision.

Different substrates require tailored wavelengths. BY Laser’s multi-wavelength laser marking machines combine fiber (1,064 nm) and UV (355 nm) sources to optimize marking on metals, polymers, and glass. Automated head switching and unified control software enable quick transitions between applications. ISO 9001-compliant manufacturing includes wavelength calibration and process validation. B2B partners benefit from a single platform covering diverse marking needs—simplifying procurement and enabling mixed-material production without tool changes.

The future of laser marking machines lies in smart automation. BY Laser is developing AI-driven marking systems that adjust laser parameters in real time based on vision-system feedback, ensuring consistent quality across variable part tolerances. IoT connectivity enables predictive maintenance, remote performance monitoring, and energy-optimization analytics. Modular designs allow integration of ultrafast and green lasers. B2B clients partnering with BY Laser gain early access to pilot programs—staying at the forefront of precision identification and Industry 4.0 marking solutions.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber (1,064 nm), UV (355 nm), CO₂ (10,600 nm), and dual-source configurations for versatile marking.

Compatible substrates include stainless steel, aluminum, plastics, glass, ceramics, and coated surfaces.

Standard interfaces: Ethernet/IP, PROFINET, EtherCAT; optional PLC and vision-system support for automation.

Preventive maintenance every 1,000 hours; replace fume filters and verify beam alignment per usage.

Enclosed marking chambers, safety interlocks, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and specification approval; expedited options available.