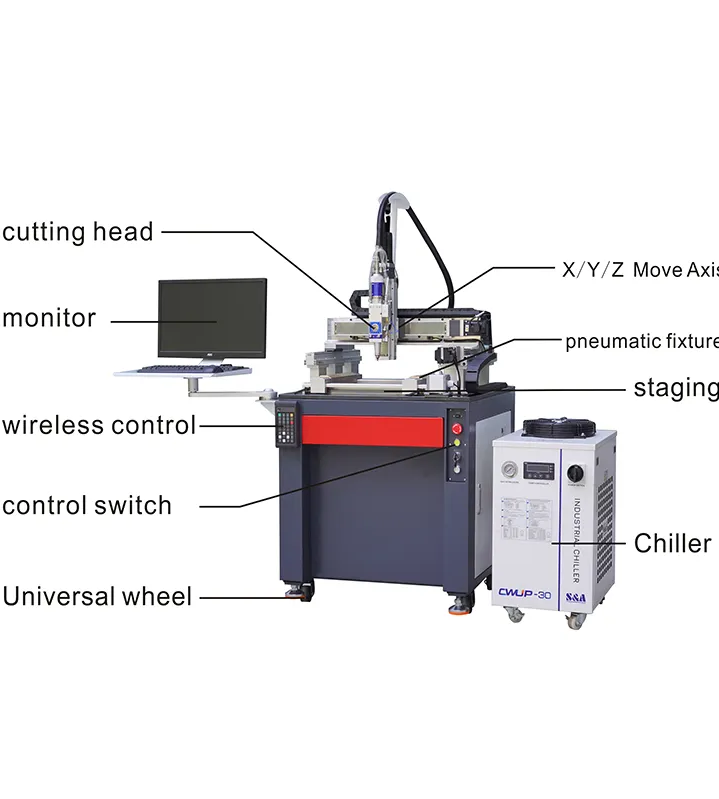

BY Laser’s laser cutter machine is engineered for high-throughput environments, combining 2 kW–6 kW fiber lasers with gantry-style motion systems capable of processing up to 200 m²/hour. Features include dynamic power modulation, conveyor-loading options, and real-time cut monitoring to maintain consistent kerf width. Built in ISO 9001 facilities, each system undergoes multi-point calibration and comes with CAD/CAM software that optimizes nesting patterns. B2B partners receive full-cycle service—site survey, installation, operator certification, and 24/7 remote support—ensuring seamless integration into your automated cutting operations.

Efficiency and reliability are at the core of BY Laser’s laser cutter machines. Designed to operate continuously in demanding environments, our machines ensure consistent cut quality and reduced downtime. With advanced cooling systems and robust structures, BY Laser delivers equipment that supports high-volume production. B2B customers gain the advantage of durable, energy-efficient laser cutter machines tailored to meet the evolving needs of their manufacturing processes.

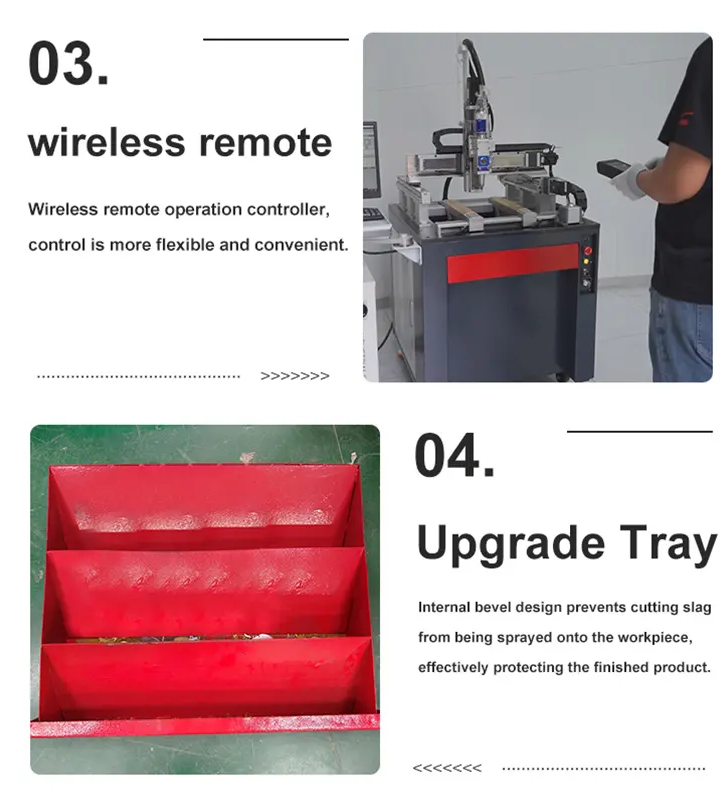

BY Laser understands that each industrial application has unique requirements. Our laser cutter machines can be customized to match specific material thicknesses, sizes, and production volumes. With BY Laser’s flexible configurations, B2B customers benefit from scalable solutions that grow with their business demands, providing maximum return on investment and consistent cutting performance.

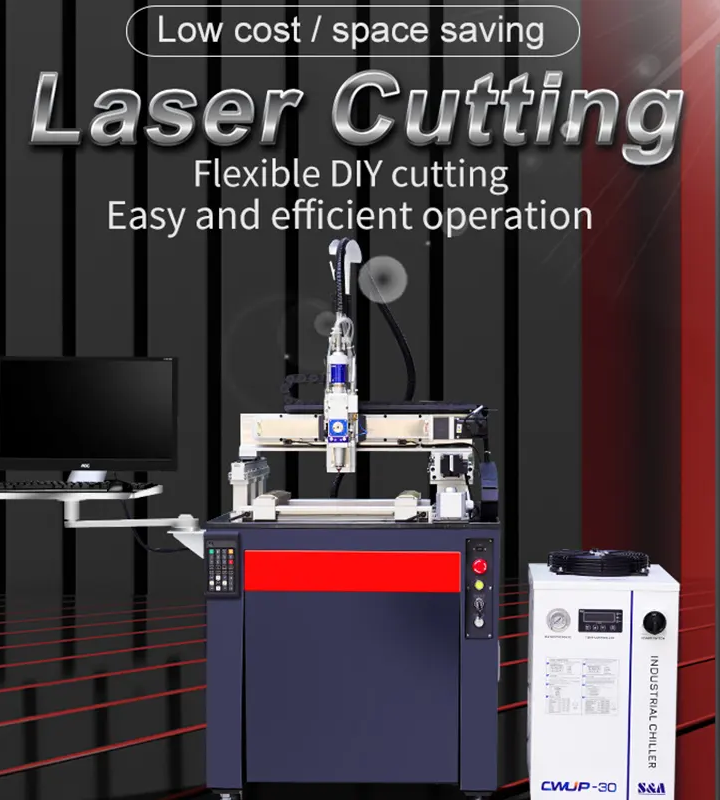

BY Laser offers state-of-the-art laser cutter machines designed to meet the precision demands of modern industrial manufacturing. Our machines utilize cutting-edge technology to deliver high-speed, accurate cuts with minimal material waste. Built for durability and efficiency, BY Laser machines empower businesses to optimize production lines and enhance product quality. As a trusted B2B partner, BY Laser focuses on scalable solutions that support large-scale manufacturing and customization needs.

Diverse industries demand versatility—from thin-film plastics to thick steel plates. BY Laser’s laser cutter machine platform supports power modules ranging from 500 W to 12 kW, interchangeable nozzles, and multi-gas assist options for oxygen, nitrogen, or air. The user interface allows pre-set parameter libraries tailored to each material and thickness. Whether you’re prototyping acrylic signage or fabricating structural beams, BY Laser’s solutions provide quick changeovers, repeatable settings, and integrated safety interlocks. B2B customers gain simplified procurement through a single supplier for all cutting needs, complete with training and spare-parts agreements.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

Our machines range from 500 W to 12 kW fiber-laser modules to suit delicate plastics up to heavy steel plate cutting.

Compatible substrates include stainless steel, aluminum, copper, acrylic, plywood, composites, and more.

Standard interfaces include Ethernet/IP, PROFINET, and OPC UA for integration with PLCs, conveyors, and robotic unloaders.

Preventive maintenance is recommended every 1,000 operating hours; filter changes and beam-path inspections vary by usage.

All units include enclosed cutting areas, interlocked doors, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and drawing approval; expedited schedules may be arranged for urgent projects.