Designed for maritime applications, BY Laser’s heavy-duty laser cleaning machine uses 1 kW fiber lasers and reinforced galvanometers to strip barnacles, corrosion, and marine fouling from ship hulls. With IP-rated enclosures, long-reach fiber delivery, and onboard dust extraction, it withstands harsh environments. ISO 9001-certified, each system includes custom-engineered mounting brackets and ATEX-compliant components. BY Laser’s B2B support includes on-site training, 24/7 remote assistance, and spare-parts agreements—ensuring uninterrupted maintenance operations and extended asset lifecycles.

Chemical and abrasive cleaning produce hazardous waste and dust. BY Laser’s laser cleaning machine eliminates the need for consumables, using only fiber lasers and electricity. Integrated HEPA and activated-carbon filters capture particulate and fume byproducts, complying with environmental regulations without secondary waste streams. ISO 14001 certification underpins our sustainable design philosophy. B2B customers can offset carbon by optimizing power consumption via real-time energy monitoring and scheduling. BY Laser’s eco-friendly cleaning solutions support your corporate responsibility goals while maintaining high cleaning performance.

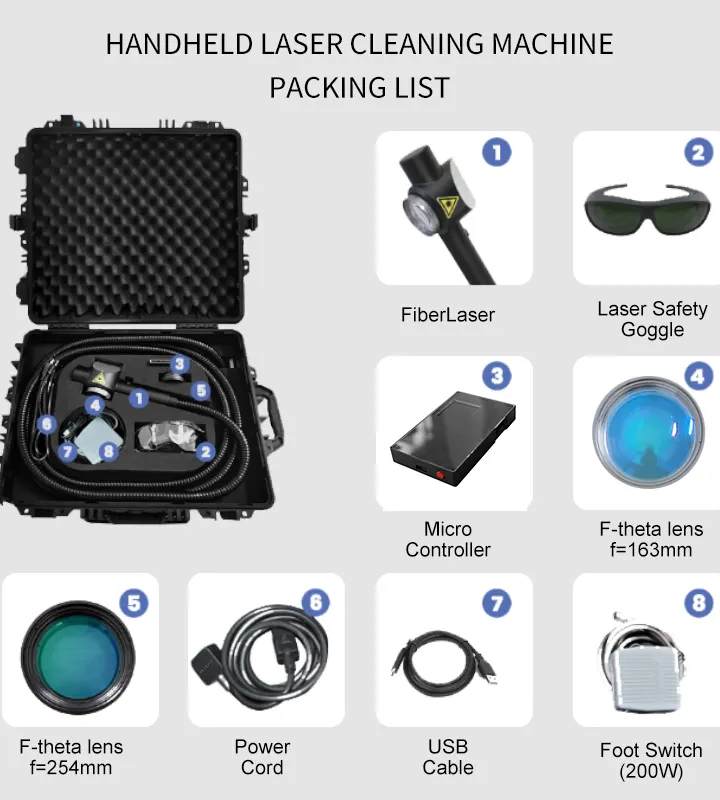

From shipyards to semiconductor fabs, cleaning requirements vary widely. BY Laser offers tailored laser cleaning machine configurations—low-power handheld units for delicate parts, mid-power table-top systems for maintenance shops, and high-power gantries for large structures. Our in-house R&D team collaborates on beam-shaping optics, specialized nozzles, and bespoke software features. Each machine is delivered with application-specific process recipes and validation reports. By partnering with BY Laser, B2B clients access a single supplier for diverse cleaning needs, simplifying procurement and support across multiple facilities.

Compact yet powerful, BY Laser’s portable laser cleaning machines bring flexibility to on-site operations. These systems are easy to maneuver and designed for applications that require mobility without compromising cleaning strength. Ideal for hard-to-reach areas or field work, our machines are trusted by businesses looking for convenient, high-efficiency cleaning solutions. BY Laser ensures every portable unit meets strict quality controls to provide consistent performance in dynamic industrial settings.

Designed for speed and accuracy, BY Laser’s fiber laser cleaning machines are built to optimize industrial cleaning tasks. These machines offer a non-abrasive alternative to traditional methods, reducing labor intensity while maintaining high-quality surface results. Trusted by manufacturers and industrial service providers, BY Laser integrates advanced optical systems and control software into every machine to support consistent and scalable B2B operations.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer 100 W to 2 kW fiber-laser modules to match applications from delicate parts cleaning to heavy rust removal.

Compatible substrates include steel, aluminum, stone, composites, ceramics, and electronic components.

Routine preventative maintenance is recommended every 1,000 operating hours; fume-filter replacement depends on usage intensity.

All machines have enclosed beam paths, interlocks, emergency stops, key switches, and vision-based presence detection.

Yes. BY Laser provides OEM integration packages, custom beam-delivery optics, and software adjustments to meet specific workflows.

Standard delivery is 8–12 weeks after order confirmation and drawing approval; expedited options may be available for urgent projects.