BY Laser’s galvanometer-driven laser marking machine achieves micro-precision engraving on medical devices, electronics, and jewelry. Our 30 W fiber-laser source paired with high-speed galvo scanners delivers sub-20 µm feature resolution at vector marking speeds up to 8 m/s. Produced under ISO 9001 protocols, each system undergoes beam-profile validation and drift-compensation calibration. B2B partners receive customizable optics, process-qualification reports, and full software suites for data coding, multi-axis synchronization, and automated batch marking.

Businesses scale in phases; capital investments must align with growth. BY Laser’s modular laser marking machines allow incremental deployment—starting with a single desktop unit and expanding to multi-head cells. Shared hardware and software simplify maintenance and training. ISO 9001 quality systems ensure interchangeability of parts and consistent performance. B2B customers enjoy lower initial investment, predictable upgrade paths, and the ability to match marking capacity with evolving production volumes—maximizing ROI.

Future-proof your production with BY Laser’s laser marking machines ready for smart factory integration. With advanced interfaces and automation compatibility, our machines support Industry 4.0 strategies. BY Laser enables B2B clients to achieve digital transformation with marking systems that enhance data management and traceability.

Ensure product traceability and quality with BY Laser’s industrial-grade laser marking machines. Our systems deliver consistent output, helping businesses meet labeling regulations and enhance product value. With strong R&D capabilities, BY Laser supports industries that demand reliability, speed, and accuracy in high-volume marking tasks.

BY Laser delivers high-performance laser marking machines tailored for industrial-scale operations. Our machines ensure precise, permanent marks on metals, plastics, and more. Designed for automation integration, BY Laser systems reduce human error and enhance production output. Trusted by manufacturers worldwide, we support diverse applications with long-term operational stability and reliable marking results.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber (1,064 nm), UV (355 nm), CO₂ (10,600 nm), and dual-source configurations for versatile marking.

Compatible substrates include stainless steel, aluminum, plastics, glass, ceramics, and coated surfaces.

Standard interfaces: Ethernet/IP, PROFINET, EtherCAT; optional PLC and vision-system support for automation.

Preventive maintenance every 1,000 hours; replace fume filters and verify beam alignment per usage.

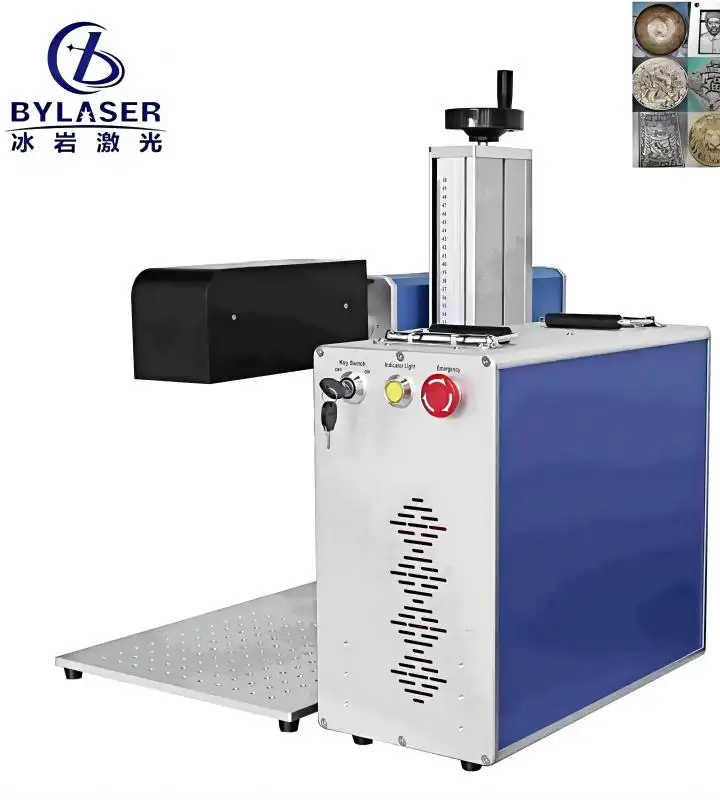

Enclosed marking chambers, safety interlocks, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and specification approval; expedited options available.