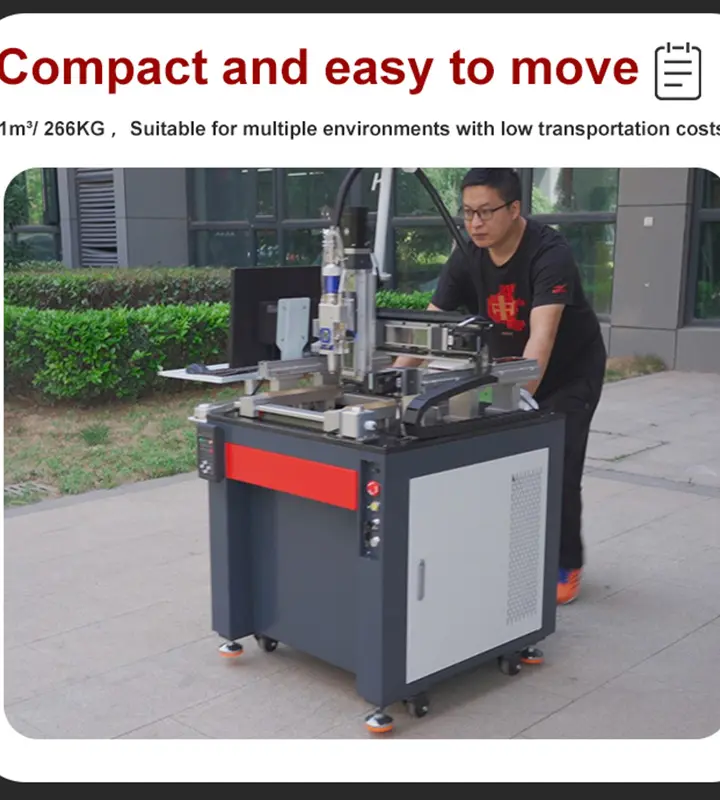

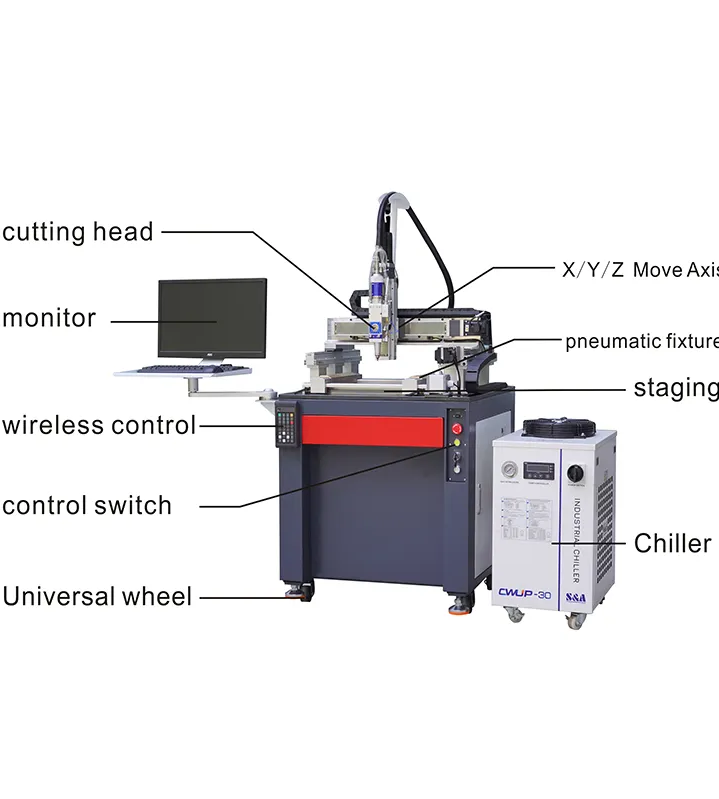

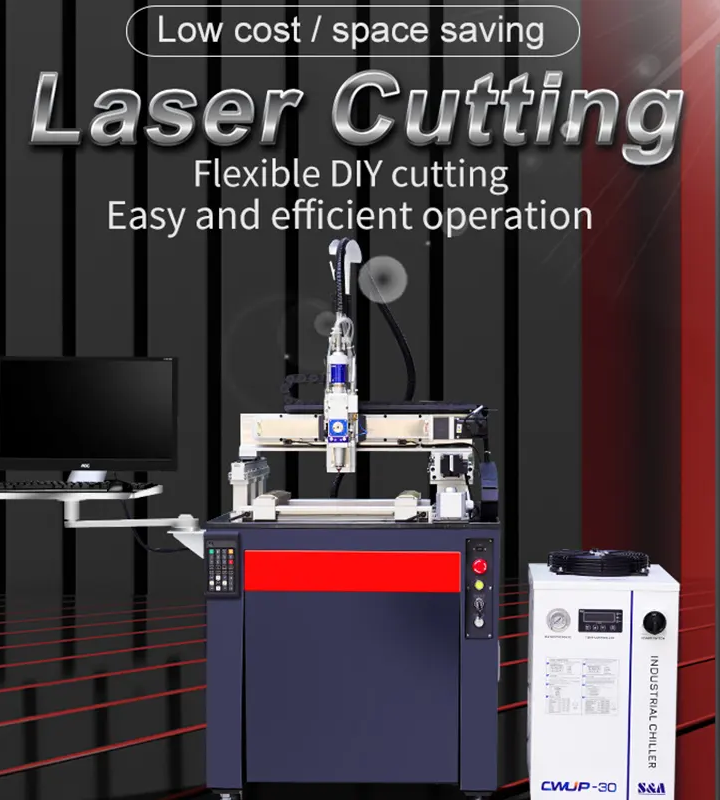

Optimize small-batch production with BY Laser’s compact laser cutter machine, featuring 500 W fiber-laser modules and a 1.5 × 3 m cutting bed. Our system includes auto-focus optics, intelligent material recognition, and dust-extraction hoods for clean operation. Manufactured under ISO 14001 environmental standards, each unit offers a user-friendly HMI, offline programming, and multi-axis attachments for bevel cutting. BY Laser provides B2B customers with customizable automation packages, preventive-maintenance training, and spare-parts kits—ensuring minimal downtime and maximum yield on diverse materials from stainless steel to plywood.

In modern factories, automation is key to efficiency. BY Laser’s laser cutter machine integrates seamlessly with PLCs, SCADA, and MES platforms via Ethernet/IP and OPC UA protocols. Conveyor feeders, part-unload robots, and vision-guided alignment units can be added to create fully autonomous cutting cells. Our systems feature real-time data logging and OEE dashboards, enabling B2B clients to monitor uptime, utilization, and quality metrics remotely. BY Laser offers turnkey automation packages—covering hardware, software, and system validation—to reduce manual handling, increase throughput, and support Industry 4.0 initiatives in cutting operations.

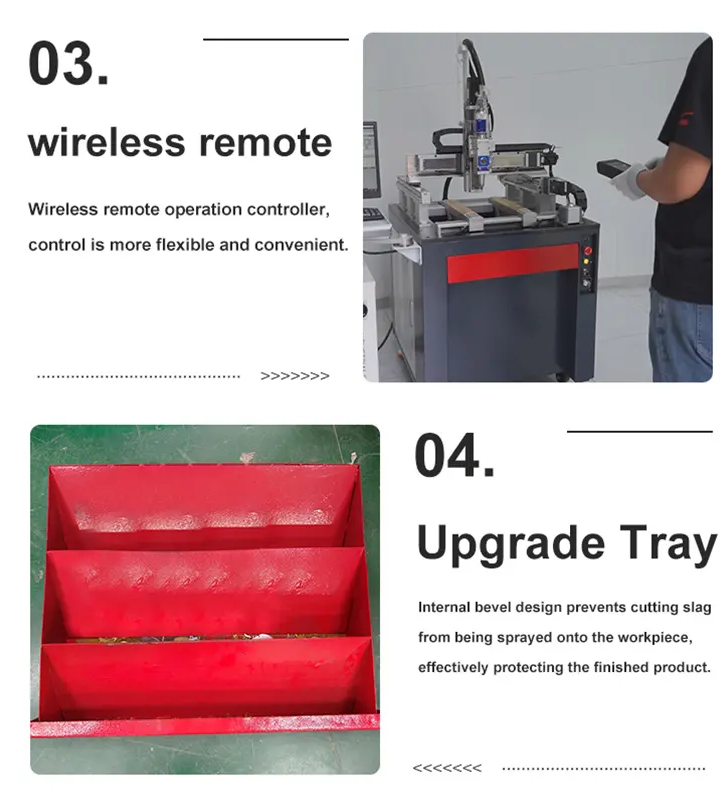

BY Laser’s laser cutter machines are engineered to handle a wide variety of materials, including metals, plastics, and composites. With user-friendly controls and smart automation, these machines reduce labor costs and improve operational efficiency. B2B clients benefit from BY Laser’s commitment to innovation, providing cutting-edge equipment that integrates seamlessly into industrial workflows and helps increase productivity without compromising precision.

In high-volume manufacturing, cutting speed directly impacts profitability. BY Laser addresses this with its laser cutter machine lineup, leveraging multi-kilowatt fiber lasers and high-acceleration servo drives for rapid traversal and minimal idle time. Our proprietary beam-shaping optics maintain beam quality over long distances, ensuring uniform power density and kerf width. Integrated CAD/CAM software automatically nests parts to reduce material waste. B2B customers benefit from predictive-maintenance alerts, remote performance monitoring, and modular upgrade paths—enabling continuous production with minimal operator intervention and optimal return on investment.

BY Laser understands that each industrial application has unique requirements. Our laser cutter machines can be customized to match specific material thicknesses, sizes, and production volumes. With BY Laser’s flexible configurations, B2B customers benefit from scalable solutions that grow with their business demands, providing maximum return on investment and consistent cutting performance.

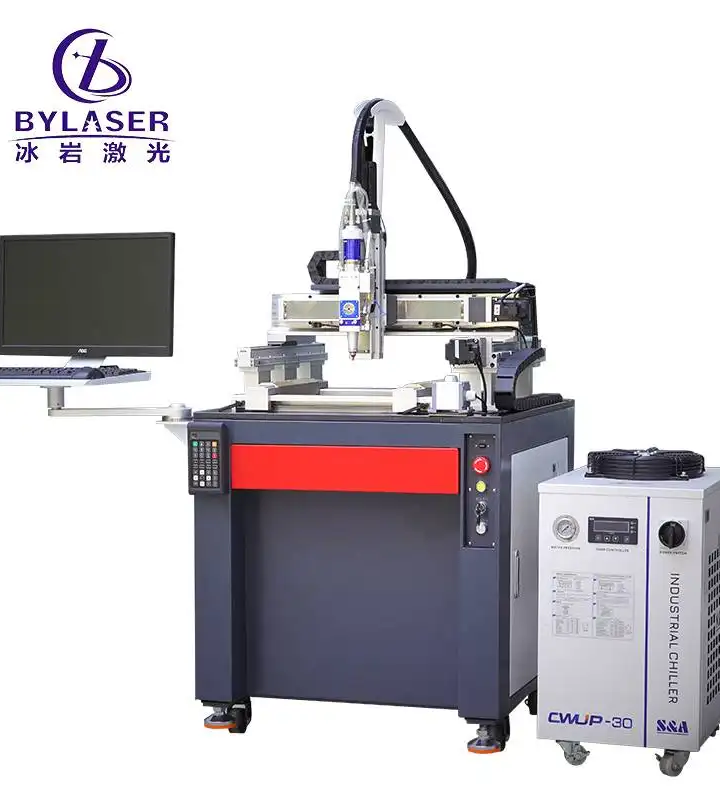

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

Our machines range from 500 W to 12 kW fiber-laser modules to suit delicate plastics up to heavy steel plate cutting.

Compatible substrates include stainless steel, aluminum, copper, acrylic, plywood, composites, and more.

Standard interfaces include Ethernet/IP, PROFINET, and OPC UA for integration with PLCs, conveyors, and robotic unloaders.

Preventive maintenance is recommended every 1,000 operating hours; filter changes and beam-path inspections vary by usage.

All units include enclosed cutting areas, interlocked doors, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and drawing approval; expedited schedules may be arranged for urgent projects.