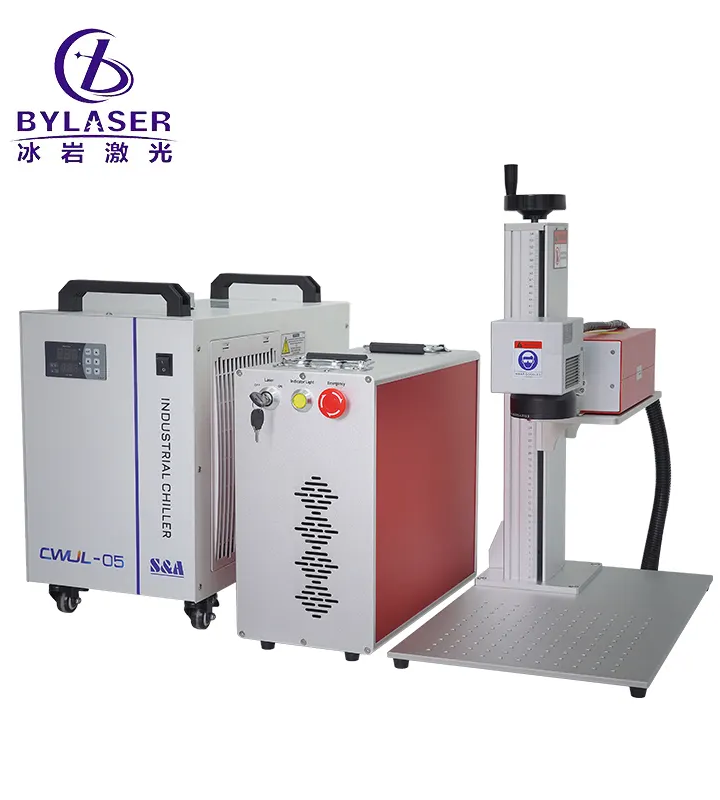

BY Laser’s laser marking machine with integrated vision guidance uses high-resolution cameras and AI-driven alignment algorithms to ensure precise mark placement on irregular parts. Featuring a 50 W fiber laser, autofocus optics, and dynamic Z-axis adjustment, it supports variable-frequency marking and 2D/3D surface compensation. ISO 9001 manufacturing ensures stability and calibration traceability. B2B partners gain vision integration, application-specific SOPs, and global field-service support—delivering consistent, high-precision marking in high-mix/low-volume production.

Traditional marking—solvent inks, labels—creates waste and requires replenishment. BY Laser’s laser marking machines operate without consumables, using only electricity and inert gas. Integrated HEPA filtration captures particulates, reducing environmental impact. ISO 14001-compliant design and energy-efficient lasers lower carbon footprint. B2B clients eliminate label stock costs, avoid hazardous-waste disposal, and bolster green credentials. Laser marking becomes a sustainable alternative, aligning with corporate responsibility goals and reducing long-term operational expenses.

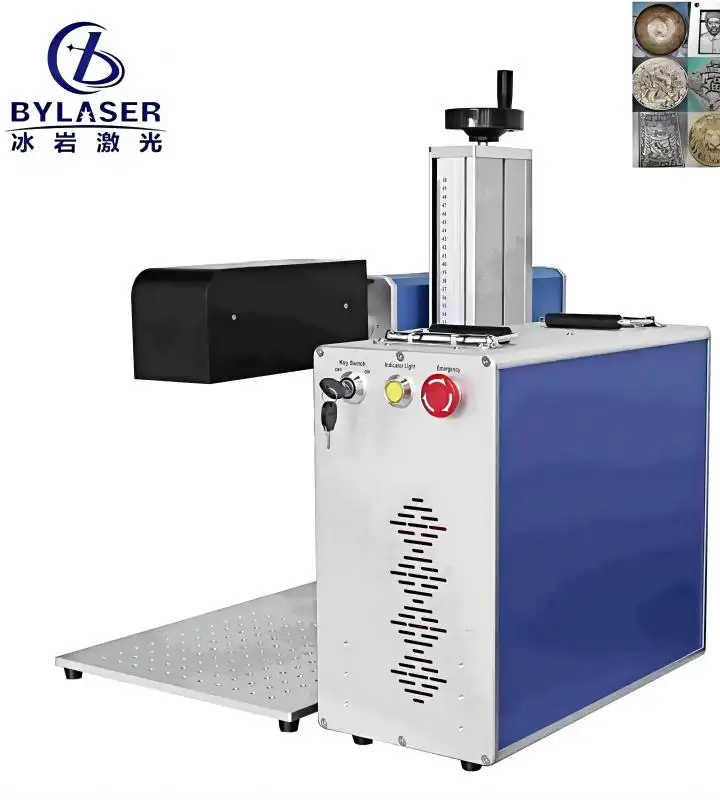

Engineered for heavy-duty use, BY Laser’s laser marking machines offer high-speed performance and superior durability. Built with advanced control systems, they support continuous marking without compromising accuracy. For B2B clients seeking scalable solutions, BY Laser provides equipment that meets the demand of modern production environments while minimizing downtime.

BY Laser delivers high-performance laser marking machines tailored for industrial-scale operations. Our machines ensure precise, permanent marks on metals, plastics, and more. Designed for automation integration, BY Laser systems reduce human error and enhance production output. Trusted by manufacturers worldwide, we support diverse applications with long-term operational stability and reliable marking results.

Every application demands specific marking solutions—deep-etch VIN plates, low-heat PCB codes, or decorative jewelry engravings. BY Laser collaborates with clients to configure laser marking machines with suitable wavelengths, beam-delivery optics, and control software. Our in-house R&D performs application testing, provides process recipes, and delivers qualification reports. With ISO 9001 quality assurance, B2B customers receive tailored marking systems that optimize speed, contrast, and durability—ensuring marks meet both functional and aesthetic requirements.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber (1,064 nm), UV (355 nm), CO₂ (10,600 nm), and dual-source configurations for versatile marking.

Compatible substrates include stainless steel, aluminum, plastics, glass, ceramics, and coated surfaces.

Standard interfaces: Ethernet/IP, PROFINET, EtherCAT; optional PLC and vision-system support for automation.

Preventive maintenance every 1,000 hours; replace fume filters and verify beam alignment per usage.

Enclosed marking chambers, safety interlocks, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and specification approval; expedited options available.