BY Laser’s laser cleaning machine is engineered for seamless integration with industrial robots and automated lines. With 500 W fiber lasers, high-precision galvo scanners, and real-time monitoring software, it delivers consistent cleaning on complex geometries. ISO 9001-certified manufacturing guarantees reliability, while our in-house R&D team provides custom beam-delivery designs. Featuring sealed fiber optics, programmable cleaning paths, and safety interlocks, BY Laser supports B2B clients with turnkey robotic cell deployment, on-site installation, and ongoing support—optimizing throughput and reducing manual labor in surface-preparation processes.

Remove rust with precision and without secondary pollution using BY Laser’s laser cleaning machines. Our systems utilize cutting-edge fiber laser technology to clean surfaces efficiently, supporting applications in manufacturing, infrastructure, and maintenance. BY Laser’s engineering team focuses on delivering durable and intelligent equipment that fits seamlessly into automated workflows, helping B2B clients increase productivity and reduce operating costs.

Consistency is critical for large B2B orders of laser cleaning machines—each unit must perform identically across sites. BY Laser enforces ISO 9001 processes, from component sourcing to final inspection. We calibrate each laser source using spectroradiometers and verify scan coherence on test fixtures. Our digital twin simulation replicates customer workflows, enabling factory acceptance tests (FAT) before shipment. With remote monitoring and software-update protocols, BY Laser maintains performance parity across distributed fleets. This reliability reduces integration risk for OEMs and industrial groups deploying multiple cleaning systems.

Transitioning from traditional methods to a laser cleaning machine requires capital investment. BY Laser helps clients quantify ROI by calculating savings on consumables, labor, and waste-disposal fees. With energy-efficient fiber lasers and minimal maintenance, payback periods often fall within 12–18 months for high-usage scenarios. Detailed case studies illustrate savings in steel fabrication, mold maintenance, and automotive refurbishing. B2B customers receive customized financial models, TCO comparisons, and project-specific forecasts—enabling data-driven decisions when adopting BY Laser cleaning solutions.

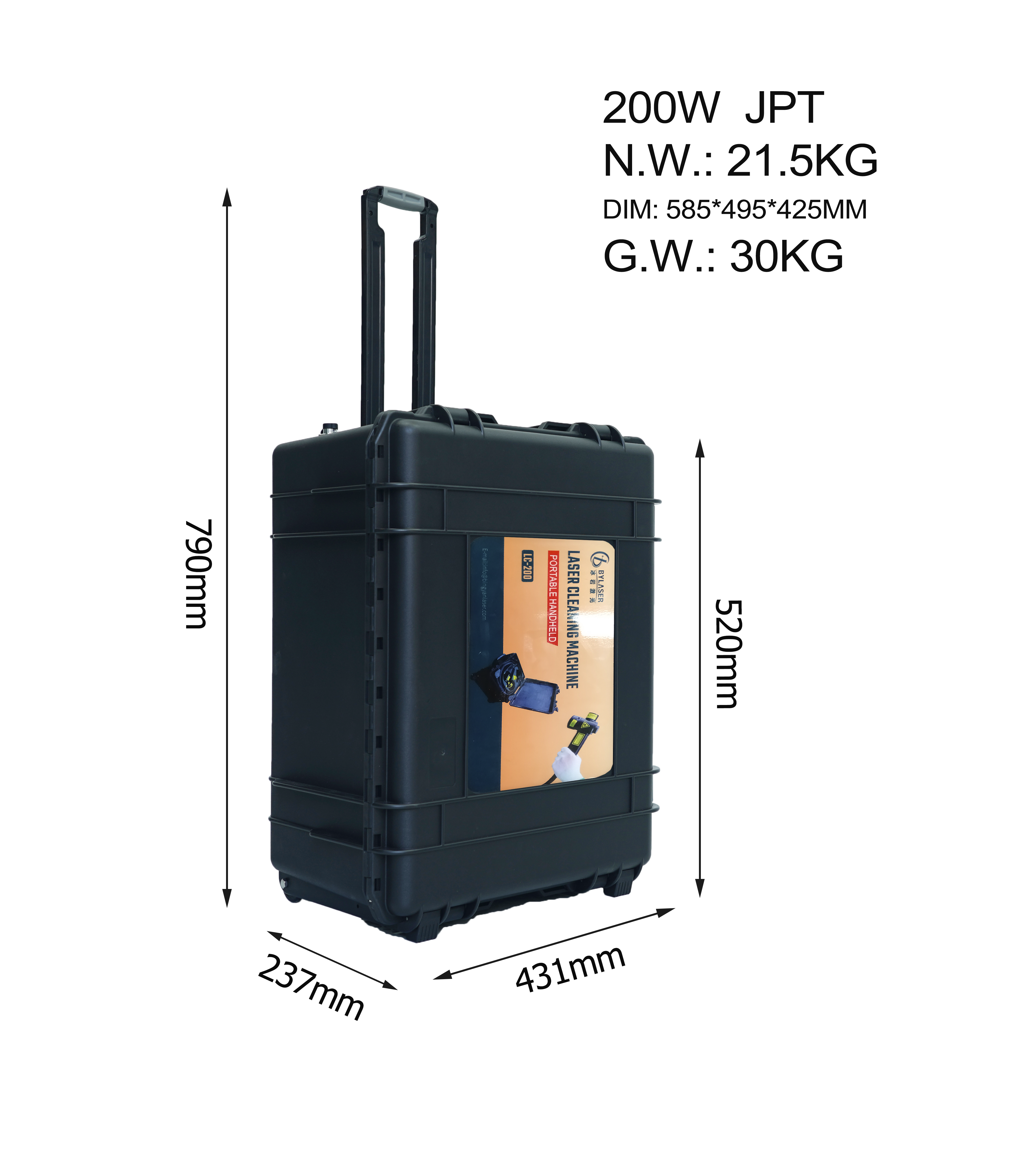

Compact yet powerful, BY Laser’s portable laser cleaning machines bring flexibility to on-site operations. These systems are easy to maneuver and designed for applications that require mobility without compromising cleaning strength. Ideal for hard-to-reach areas or field work, our machines are trusted by businesses looking for convenient, high-efficiency cleaning solutions. BY Laser ensures every portable unit meets strict quality controls to provide consistent performance in dynamic industrial settings.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer 100 W to 2 kW fiber-laser modules to match applications from delicate parts cleaning to heavy rust removal.

Compatible substrates include steel, aluminum, stone, composites, ceramics, and electronic components.

Routine preventative maintenance is recommended every 1,000 operating hours; fume-filter replacement depends on usage intensity.

All machines have enclosed beam paths, interlocks, emergency stops, key switches, and vision-based presence detection.

Yes. BY Laser provides OEM integration packages, custom beam-delivery optics, and software adjustments to meet specific workflows.

Standard delivery is 8–12 weeks after order confirmation and drawing approval; expedited options may be available for urgent projects.