Integrate BY Laser’s laser welding machine into robotic production cells for fully automated joint formation. With 2 kW continuous-wave fiber lasers, high-speed galvo scanners, and EtherCAT connectivity, it delivers consistent welds on complex geometries. ISO 9001-certified manufacturing ensures system reliability, while our in-house R&D provides custom beam-delivery optics and welding recipes. Featuring safety enclosures, programmable seam tracking, and real-time weld monitoring, BY Laser supports B2B clients with turnkey robotic integration, on-site commissioning, and operator certification—enhancing throughput and reducing manual labor in industrial welding applications.

With a strong focus on quality and innovation, BY Laser has become a reliable supplier of laser welding machines to B2B enterprises worldwide. Our machines are manufactured with strict quality control and are adaptable to a wide range of industrial applications. Partnering with BY Laser means accessing advanced welding technology and dependable service support.

BY Laser’s automated laser welding machines are designed to improve efficiency and reduce labor costs. Integrated with intelligent control systems, our machines support automation in demanding production environments. With high repeatability and minimal maintenance, BY Laser enables B2B customers to embrace smarter, more sustainable manufacturing processes.

BY Laser welding machines are trusted by global B2B clients for their stability, precision, and efficiency. Built with high-end components and smart control systems, they streamline production and reduce material waste. Whether for automotive parts, electronic components, or customized metal fabrication, BY Laser provides reliable machines that enhance your competitive edge.

Speed and accuracy are vital in modern production lines. BY Laser’s laser welding machines are engineered to deliver high-speed welding without compromising on quality. Ideal for high-throughput operations, our machines ensure smooth seams and strong joints. BY Laser helps industrial clients meet production goals while maintaining exceptional welding performance.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber-laser sources from 200 W to 4 kW to suit micro-welding and heavy-plate applications.

Compatible substrates include stainless steel, aluminum, titanium, copper, and nickel alloys.

Standard interfaces: EtherCAT, PROFINET; optional PLC, robotic-arm integration, and inline seam-tracking sensors.

Preventive maintenance every 1,000 hours; replace protective windows and fume filters based on usage.

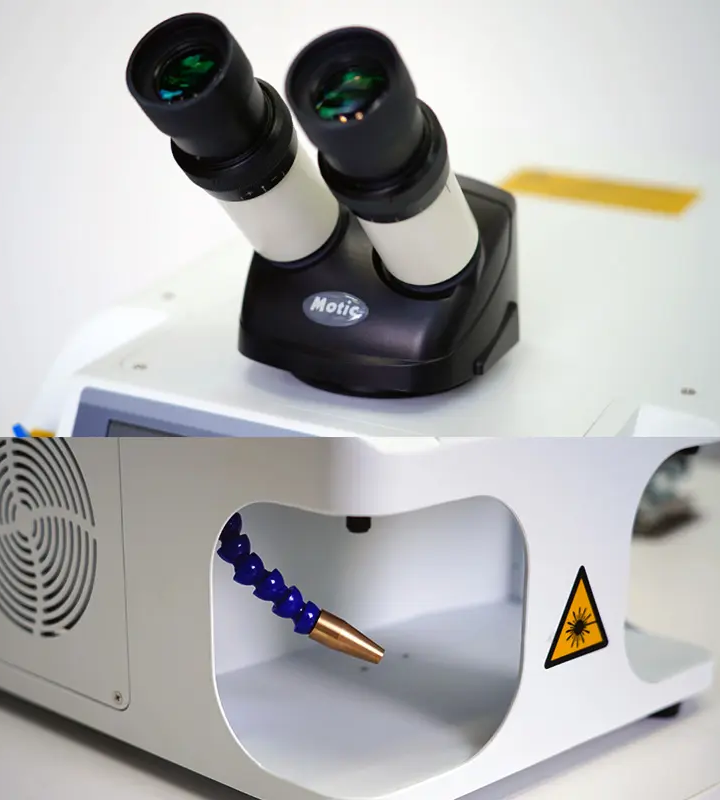

Enclosed welding cells, interlocked doors, emergency stops, key-switch controls, and fume extraction.

Standard delivery is 8–10 weeks after order confirmation and weld-parameter approval; expedited options available.