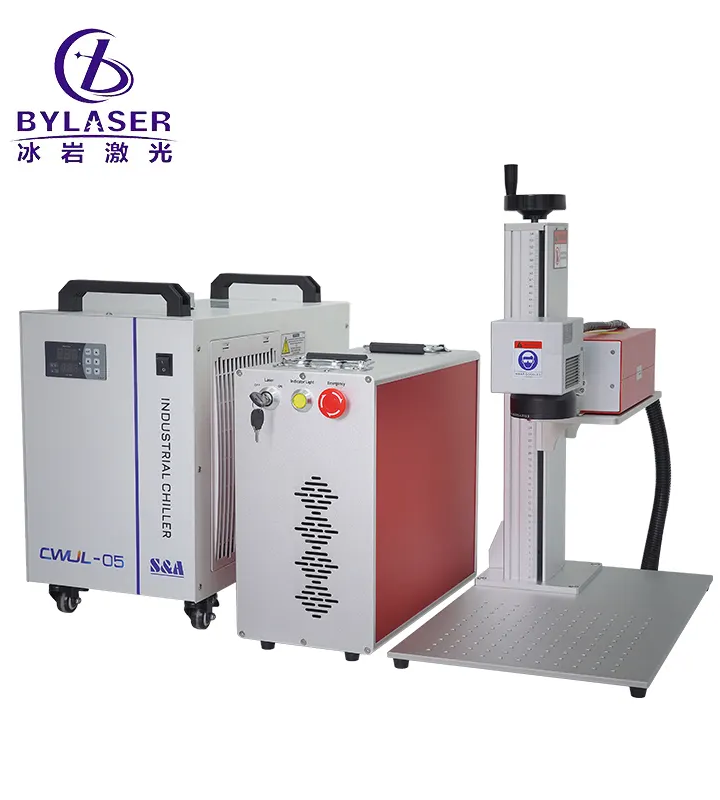

BY Laser’s galvanometer-driven laser marking machine achieves micro-precision engraving on medical devices, electronics, and jewelry. Our 30 W fiber-laser source paired with high-speed galvo scanners delivers sub-20 µm feature resolution at vector marking speeds up to 8 m/s. Produced under ISO 9001 protocols, each system undergoes beam-profile validation and drift-compensation calibration. B2B partners receive customizable optics, process-qualification reports, and full software suites for data coding, multi-axis synchronization, and automated batch marking.

Effective part identification is vital for quality control and warranty tracking. BY Laser provides laser marking machines that deliver permanent, high-resolution marks—serial numbers, DataMatrix codes, and logos—on diverse substrates. Our fiber-laser and UV-laser options integrate easily into production lines via Ethernet/IP and OPC UA, enabling automatic marking during assembly. Backed by ISO 9001-certified manufacturing and remote-monitoring capabilities, B2B clients reduce rework, improve traceability, and meet industry regulations with minimal operator intervention.

Different substrates require tailored wavelengths. BY Laser’s multi-wavelength laser marking machines combine fiber (1,064 nm) and UV (355 nm) sources to optimize marking on metals, polymers, and glass. Automated head switching and unified control software enable quick transitions between applications. ISO 9001-compliant manufacturing includes wavelength calibration and process validation. B2B partners benefit from a single platform covering diverse marking needs—simplifying procurement and enabling mixed-material production without tool changes.

Sustainability meets performance with BY Laser’s energy-efficient laser marking machines. Our systems consume less power while maintaining excellent marking quality. BY Laser helps B2B partners reduce their environmental footprint without compromising operational goals, making our solutions both responsible and productive.

BY Laser understands that every business has unique marking requirements. Our laser marking machines are adaptable to various materials and production volumes. Whether for serial numbers, barcodes, or logos, our systems provide high-resolution markings that meet industry standards. BY Laser offers customizable solutions for clients across manufacturing sectors.

As a genuine laser equipment manufacturer, BY Laser offers a seamless experience from research and development to sales. This integrated approach ensures a streamlined product development cycle, ensuring that our machines are cutting-edge and tailored to our customers' needs.

BY Laser provides beautiful pricing that eliminates any middleman price difference, ensuring you get the best value for your investment. We believe in offering high-quality machines and services without compromising on cost, making us a cost-effective choice for your laser marking requirements.

We excel in exceptional customer service. Our skilled tech team offers assistance with free training, technical support, and troubleshooting. From selection to long-term use, BY Laser ensures a seamless and fulfilling experience with your laser marking equipment.

Advanced laser technology ensures exact, reliable cleaning results.

Achieves rapid marking speeds, enhancing productivity.

Ensures accurate and clean cuts with minimal material waste.

Reduces thermal distortion, preserving material integrity.

We offer fiber (1,064 nm), UV (355 nm), CO₂ (10,600 nm), and dual-source configurations for versatile marking.

Compatible substrates include stainless steel, aluminum, plastics, glass, ceramics, and coated surfaces.

Standard interfaces: Ethernet/IP, PROFINET, EtherCAT; optional PLC and vision-system support for automation.

Preventive maintenance every 1,000 hours; replace fume filters and verify beam alignment per usage.

Enclosed marking chambers, safety interlocks, emergency stops, key switches, and optional laser-safety curtains.

Standard delivery is 8–10 weeks after order confirmation and specification approval; expedited options available.