Modern industrial cleaning has evolved dramatically from traditional chemical and mechanical methods to advanced laser-based technologies. Pulse laser cleaning machines represent a revolutionary approach to surface preparation and contaminant removal, offering precision, efficiency, and environmental benefits that traditional methods simply cannot match. These sophisticated systems utilize controlled bursts of laser energy to remove rust, paint, coatings, and other surface contaminants without damaging the underlying substrate. The versatility and effectiveness of these machines have made them increasingly popular across numerous industries seeking cleaner, faster, and more sustainable cleaning solutions.

The technology behind pulse laser cleaning operates on the principle of selective photothermolysis, where short bursts of high-intensity laser light interact with surface contaminants. Unlike continuous wave lasers, pulse laser cleaning machines deliver energy in discrete pulses, allowing for better heat dissipation and more controlled material removal. This pulsed approach minimizes thermal damage to the base material while maximizing cleaning efficiency. The process is entirely dry, eliminating the need for chemicals, abrasives, or water, making it an environmentally responsible choice for industrial applications.

The automotive industry has embraced pulse laser cleaning machines for their exceptional ability to remove rust and corrosion from metal components without affecting the underlying material properties. Classic car restoration projects particularly benefit from this technology, as it can selectively remove decades of rust while preserving original metal thickness and surface integrity. Manufacturing facilities use these systems to prepare parts for welding, coating, or assembly processes, ensuring optimal adhesion and joint quality.

Vehicle manufacturers increasingly rely on laser cleaning for production line applications where precise surface preparation is critical. The technology excels at removing mill scale, oxidation, and protective films from stamped parts before painting or coating operations. This precision cleaning ensures consistent surface quality and improves the longevity of protective coatings applied during manufacturing.

Traditional paint removal methods often involve hazardous chemicals or aggressive mechanical processes that can damage underlying surfaces. Pulse laser cleaning machines offer a safer, more controlled alternative for removing multiple layers of paint, primers, and protective coatings from automotive components. The technology can selectively remove specific coating layers while leaving others intact, enabling partial refinishing operations without complete component stripping.

Body shops and restoration facilities find particular value in the precision control offered by laser cleaning systems. Technicians can adjust parameters to remove only damaged or unwanted coating layers, preserving original factory finishes where possible. This capability significantly reduces preparation time and material costs while improving the quality of refinishing operations.

Aerospace applications demand the highest levels of precision and material integrity, making pulse laser cleaning machines ideally suited for aircraft maintenance and overhaul operations. These systems excel at removing thermal barrier coatings, corrosion, and contaminants from turbine blades, engine components, and structural elements without introducing mechanical stress or dimensional changes. The non-contact nature of laser cleaning eliminates concerns about tool wear or contamination transfer between components.

Maintenance facilities appreciate the ability to clean complex geometries and hard-to-reach areas that would be impossible to address with conventional methods. Laser cleaning can access internal passages, cooling holes, and intricate surface features without disassembly, reducing maintenance time and costs while improving cleaning thoroughness.

Welding and bonding operations in aerospace applications require absolutely pristine surface conditions to ensure joint integrity and reliability. Pulse laser cleaning machines provide the precision needed to prepare surfaces for critical structural joints, removing oxides, oils, and microscopic contaminants that could compromise bond strength. The technology enables consistent surface preparation across complex geometries and mixed material assemblies.

Quality control benefits significantly from laser cleaning consistency, as the process parameters can be precisely controlled and repeated across multiple components. This repeatability ensures uniform surface conditions for adhesive bonding, welding, and other joining processes critical to aircraft safety and performance.

Marine environments present unique challenges for surface maintenance due to constant exposure to saltwater, UV radiation, and biological fouling. Pulse laser cleaning machines offer an effective solution for removing marine growth, corrosion, and failed coating systems from vessel hulls and deck structures. The technology works effectively on various marine materials including steel, aluminum, and composite structures commonly found in modern vessels.

Shipyard operations benefit from the speed and efficiency of laser cleaning systems, particularly during dry dock maintenance periods where time constraints are critical. The elimination of chemical strippers and abrasive blasting reduces environmental concerns and simplifies waste disposal procedures, important considerations in marine environments where regulatory compliance is strictly enforced.

Offshore oil and gas platforms operate in extremely harsh environments where traditional maintenance methods are often impractical or dangerous. Pulse laser cleaning machines provide a safer alternative for maintaining critical infrastructure components, removing corrosion and preparing surfaces for protective coating application. The portable nature of modern laser cleaning systems enables on-site maintenance without the need for component removal or specialized containment systems.

Environmental benefits become particularly important in offshore applications where chemical discharge restrictions are stringent. Laser cleaning produces no hazardous waste streams and eliminates the risk of chemical spills or contamination of marine ecosystems. This environmental compatibility makes the technology increasingly attractive for offshore maintenance contracts where sustainability requirements are paramount.

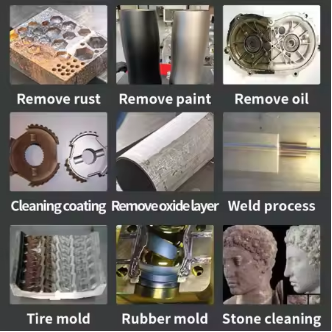

Manufacturing operations rely heavily on molds, dies, and tooling that require regular cleaning to maintain product quality and dimensional accuracy. Pulse laser cleaning machines excel at removing release agents, polymer residues, and oxidation from complex tooling geometries without affecting critical dimensions or surface finishes. The precision control available with laser systems enables selective cleaning of specific areas while protecting delicate features or coatings.

Injection molding operations particularly benefit from laser cleaning capabilities, as the technology can remove built-up polymer residues from intricate mold cavities and cooling channels. This thorough cleaning extends mold life, improves part quality, and reduces cycle times by eliminating the need for frequent mold changes or extensive manual cleaning procedures.

Welding operations require clean surfaces free from oxides, oils, and other contaminants that can compromise weld quality and strength. Pulse laser cleaning machines provide precise surface preparation capabilities that ensure optimal weld penetration and fusion characteristics. The technology can clean complex joint geometries and prepare surfaces immediately before welding, eliminating contamination concerns associated with pre-cleaned parts storage.

Post-weld cleaning applications also benefit from laser technology, particularly for removing heat tint, oxidation, and spatter from finished welds. This cleaning improves the appearance of welded assemblies and prepares surfaces for subsequent coating or finishing operations. The precision control available with pulse systems enables selective cleaning without affecting surrounding base material or previously applied finishes.

Cultural heritage preservation requires extremely gentle yet effective cleaning methods that can remove decades or centuries of environmental contamination without damaging original materials. Pulse laser cleaning machines have revolutionized restoration work by enabling precise removal of biological growth, pollution deposits, and failed conservation treatments from stone, metal, and composite monuments. The technology allows conservators to work with unprecedented precision, removing contamination layers while preserving original surface textures and details.

Museums and restoration facilities value the non-invasive nature of laser cleaning, which eliminates mechanical stress and chemical exposure concerns associated with traditional methods. The ability to adjust cleaning parameters for different materials and contamination types enables comprehensive restoration projects involving mixed-material artifacts and structures.

Archaeological artifacts often require delicate cleaning to remove soil deposits, corrosion products, and previous conservation materials while preserving original surfaces and inscriptions. Pulse laser cleaning machines provide the precision and control needed for these sensitive applications, enabling conservators to reveal hidden details and inscriptions that would be impossible to expose using conventional methods.

The documentation benefits of laser cleaning extend beyond the cleaning process itself, as the precise parameter control enables reproducible results and detailed record-keeping for conservation archives. This documentation capability supports academic research and long-term preservation planning for significant cultural artifacts.

Electronics manufacturing requires exceptional cleanliness standards to ensure reliable operation and prevent contamination-related failures. Pulse laser cleaning machines offer precise removal of flux residues, oxidation, and organic contaminants from circuit boards and electronic components without thermal damage or dimensional changes. The technology enables cleaning of dense component arrays and micro-scale features that would be impossible to address with conventional methods.

Rework and repair operations particularly benefit from laser cleaning capabilities, as the technology can selectively remove solder masks, coatings, and contaminants from specific areas without affecting surrounding components. This precision enables component replacement and circuit modification operations that maintain original manufacturing quality standards.

Optical components and precision instruments require contamination-free surfaces to maintain performance specifications and measurement accuracy. Pulse laser cleaning machines provide the gentle yet effective cleaning needed for these sensitive applications, removing organic films, particulate contamination, and degraded coatings without surface damage or optical distortion.

The technology enables in-situ cleaning of installed optical systems, eliminating the need for disassembly and realignment procedures that can introduce additional contamination or alignment errors. This capability is particularly valuable for scientific instruments and optical systems where maintaining calibration and performance standards is critical.

Pulse laser cleaning machines work effectively on a wide range of materials including steel, aluminum, titanium, copper, stone, ceramics, and many composite materials. The technology is particularly effective at removing rust, paint, coatings, biological growth, and various types of surface contamination. However, the specific laser parameters must be adjusted based on the substrate material and contamination type to ensure optimal cleaning results without surface damage.

Pulse laser cleaning machines offer significant safety advantages over traditional methods by eliminating chemical exposure, reducing physical hazards, and minimizing waste generation. The process produces no hazardous fumes or chemical residues, and proper safety protocols focus primarily on laser safety rather than chemical handling. However, appropriate eye protection and safety training remain essential for safe operation of any laser cleaning system.

The effectiveness of pulse laser cleaning depends on several key factors including laser wavelength, pulse duration, energy density, and repetition rate. The absorption characteristics of both the contamination and substrate materials play crucial roles in determining optimal parameters. Environmental conditions, contamination thickness, and surface geometry also influence cleaning effectiveness and parameter selection for specific applications.

Many modern pulse laser cleaning machines are designed for operation in challenging environments including outdoor, marine, and industrial settings. Ruggedized systems feature environmental protection, temperature compensation, and portable designs that enable effective operation in conditions where traditional cleaning methods would be impractical. However, specific environmental capabilities vary between different system designs and should be verified for particular application requirements.