In today's competitive manufacturing landscape, selecting the right fiber laser marking machine for high-speed production requires careful consideration of multiple technical and operational factors. These advanced marking systems have revolutionized industrial marking applications by delivering exceptional precision, speed, and reliability across diverse materials and production environments. Understanding the key specifications and capabilities that distinguish premium marking solutions from standard alternatives is essential for maximizing production efficiency and ensuring consistent marking quality throughout extended manufacturing cycles.

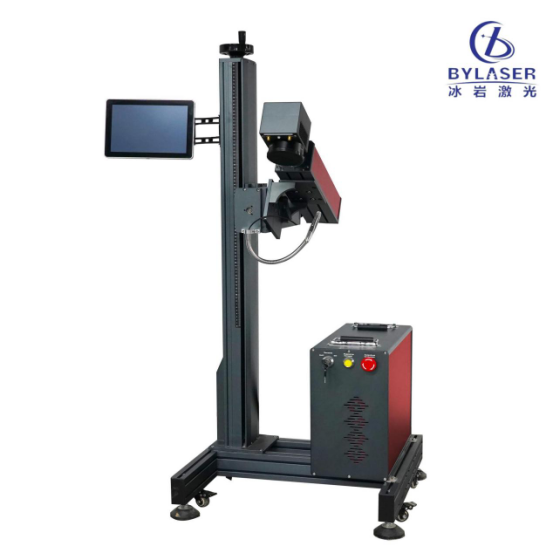

The laser power output directly influences marking speed and depth capabilities across different material types. Industrial-grade systems typically range from 20W to 100W, with higher power ratings enabling faster processing speeds on metals, plastics, and composite materials. Beam quality, measured by the M² factor, determines focusing precision and marking consistency, with values closer to 1.0 indicating superior beam characteristics for fine detail work.

Advanced fiber laser sources incorporate sophisticated beam shaping technologies that optimize energy distribution across the marking field. This ensures uniform marking quality regardless of position within the working area, while maintaining consistent depth and contrast throughout production runs. Temperature stability and active cooling systems further enhance beam quality by minimizing thermal fluctuations that could affect marking precision during continuous operation.

High-speed production environments demand marking systems capable of processing thousands of parts per hour while maintaining consistent quality standards. Galvanometer scanner technology plays a crucial role in achieving rapid positioning speeds, with premium systems offering scanning rates exceeding 10,000 mm/s for simple geometric patterns. Complex marking patterns may require adjusted speeds to ensure proper material interaction and marking depth.

Software optimization features significantly impact overall throughput by minimizing positioning delays and optimizing marking sequences. Advanced control systems can automatically adjust parameters based on material type and marking requirements, reducing setup time between product changeovers. Integration with production line control systems enables seamless communication and synchronization with upstream and downstream processes.

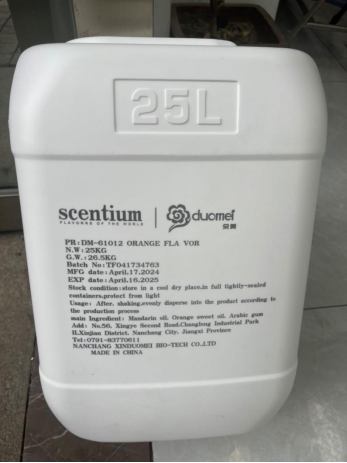

A quality fiber laser marking machine excels in processing various metal substrates including stainless steel, aluminum, titanium, and hardened tool steels. Each material requires specific parameter optimization to achieve desired marking characteristics, from subtle surface etching to deep engraving applications. Pulse frequency, power density, and scanning speed must be carefully balanced to prevent thermal damage while ensuring adequate marking contrast.

Annealing marking techniques enable permanent identification on sensitive metal components without compromising material properties or surface integrity. This approach proves particularly valuable in aerospace, medical device, and precision engineering applications where structural integrity cannot be compromised. Advanced systems offer preset parameter libraries for common metal types, streamlining setup procedures and ensuring consistent results across production batches.

Modern manufacturing increasingly relies on plastic and composite components that require permanent identification for traceability and quality control purposes. Fiber laser systems demonstrate excellent compatibility with engineering plastics including ABS, polycarbonate, nylon, and PEEK materials. Color change marking creates high-contrast identification without material removal, preserving component strength and surface finish quality.

Foaming techniques generate raised marking patterns on certain plastic formulations, creating tactile identification features for accessibility applications. Parameter control becomes critical when processing thermally sensitive materials to prevent melting, discoloration, or dimensional changes that could affect component functionality. Real-time monitoring systems can detect and compensate for material variations to maintain consistent marking quality.

Seamless integration with existing production infrastructure requires comprehensive connectivity options including Ethernet, RS-232, and industrial fieldbus protocols. Modern marking systems support communication with PLCs, MES systems, and quality control databases to enable automated parameter selection and production tracking. Real-time data exchange capabilities facilitate immediate feedback on marking quality and system performance metrics.

Conveyor integration systems enable continuous marking of parts in motion, significantly increasing throughput compared to static marking configurations. Advanced vision systems can automatically detect part positioning and orientation, adjusting marking coordinates in real-time to compensate for placement variations. This automation reduces manual intervention requirements while ensuring consistent marking placement accuracy across all processed components.

Integrated quality verification systems utilize machine vision technology to automatically inspect marking quality immediately after processing. These systems can detect issues such as incomplete characters, dimensional variations, or contrast deficiencies, triggering automatic rejection or rework procedures. Statistical process control features track marking parameters over time, identifying trends that might indicate maintenance requirements or parameter drift.

Predictive maintenance capabilities monitor laser source performance, scanner wear patterns, and cooling system efficiency to prevent unexpected downtime. Advanced diagnostic systems provide early warning indicators for component replacement scheduling, enabling proactive maintenance during planned production breaks. Data logging features maintain comprehensive records of all marking operations for quality auditing and process improvement initiatives.

Intuitive software interfaces significantly impact operator productivity and reduce training requirements for new personnel. Modern marking systems feature graphical programming environments that allow complex marking patterns to be created through drag-and-drop operations rather than traditional coding approaches. Template libraries provide starting points for common marking applications, while custom pattern creation tools enable unique design requirements to be implemented quickly.

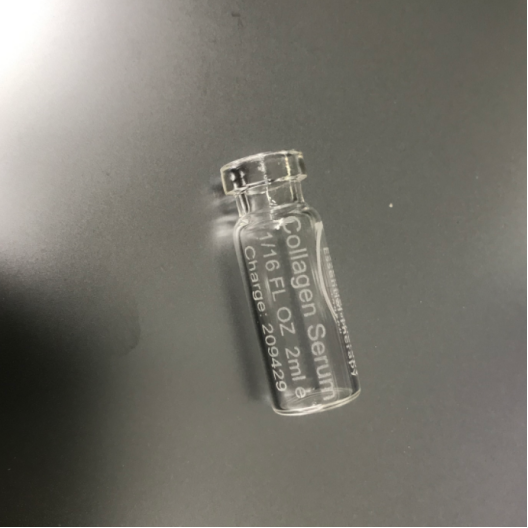

Variable data capabilities enable automatic insertion of serial numbers, date codes, barcodes, and database-driven content into marking patterns. Advanced systems support multiple data sources simultaneously, allowing complex marking layouts that combine static graphics with dynamic information. Font libraries and vector import capabilities ensure compatibility with existing design assets and corporate branding requirements.

Modern production environments increasingly require remote monitoring and control capabilities for distributed manufacturing operations. Web-based interfaces enable authorized personnel to monitor system status, adjust parameters, and download production reports from any network-connected device. Secure VPN connectivity allows technical support personnel to provide remote assistance, reducing response times for troubleshooting and optimization activities.

Cloud-based data storage and analytics platforms enable comprehensive production analysis across multiple marking stations and facilities. Machine learning algorithms can identify optimization opportunities and automatically suggest parameter adjustments based on historical performance data. Integration with enterprise resource planning systems facilitates automated scheduling and resource allocation based on production demands and marking system availability.

Comprehensive cost analysis must consider initial equipment acquisition costs alongside ongoing operational expenses including electricity consumption, maintenance requirements, and consumable replacement schedules. High-quality fiber laser marking machine systems typically demonstrate superior energy efficiency compared to alternative marking technologies, reducing long-term operating costs despite higher initial investments. Laser source longevity often exceeds 100,000 hours of operation, minimizing replacement frequency and associated downtime costs.

Maintenance requirements vary significantly between different system designs, with sealed laser sources and contactless marking processes generally requiring minimal routine service compared to mechanical marking alternatives. Predictive maintenance capabilities can further reduce unexpected repair costs by identifying potential issues before they result in production interruptions. Training costs should also be evaluated, as intuitive software interfaces can significantly reduce the time required for operator certification.

High-speed marking capabilities directly translate to increased production throughput, enabling manufacturers to meet growing demand without proportional increases in labor costs or facility requirements. Consistent marking quality reduces rejection rates and rework expenses while improving customer satisfaction and brand reputation. Automated quality verification systems minimize human inspection requirements, further reducing labor costs while ensuring comprehensive quality control coverage.

Traceability improvements enabled by permanent laser marking facilitate better inventory management, recall procedures, and quality investigation processes. These benefits often justify marking system investments through reduced liability exposure and improved operational efficiency. Integration capabilities can eliminate manual data entry processes, reducing errors and improving production planning accuracy throughout manufacturing operations.

Modern fiber laser marking machines can achieve scanning speeds exceeding 10,000 mm/s for simple patterns, with actual throughput depending on marking complexity, material type, and required depth. Production rates of 3,000-5,000 parts per hour are common for standard identification marking applications, while complex graphics or deep engraving may reduce throughput proportionally.

Laser power selection depends on material type, marking depth requirements, and desired production speed. Metals typically require 20-50W for surface marking, while deep engraving may benefit from higher power levels. Plastics often require lower power settings to prevent thermal damage, making 20-30W systems suitable for most polymer applications.

Fiber laser sources require minimal maintenance due to their sealed construction and solid-state design. Regular cleaning of protective windows, periodic calibration verification, and cooling system maintenance comprise the primary service requirements. Most systems include diagnostic tools that monitor component health and provide maintenance scheduling recommendations based on actual operating conditions.

Advanced fiber laser marking systems can accommodate curved surfaces through dynamic focus adjustment and multi-axis positioning capabilities. 3D marking software can compensate for surface variations, while rotary fixtures enable cylindrical part marking. Complex geometries may require custom fixturing solutions to ensure consistent marking quality across all surface areas.