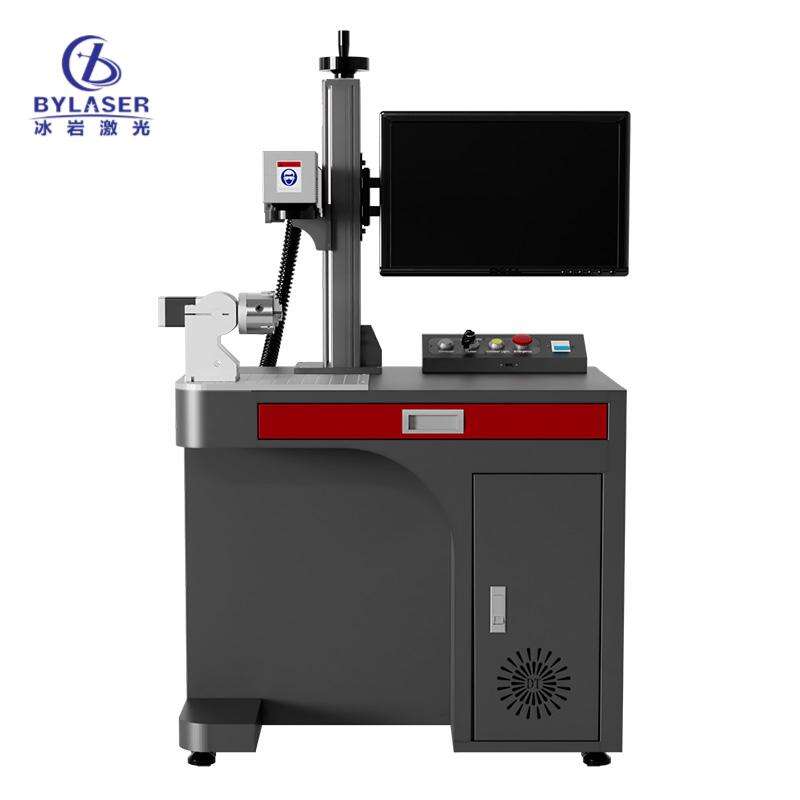

uv laser marking price

UV laser marking price encompasses various factors that determine the cost of implementing this advanced marking technology. The system utilizes ultraviolet laser technology operating at wavelengths around 355nm, making it ideal for high-precision marking on sensitive materials. The price typically ranges from $15,000 to $50,000, depending on the system's specifications, power output, and additional features. These systems excel in creating permanent, high-contrast marks on various materials including plastics, glass, ceramics, and sensitive electronic components. The technology offers exceptional marking quality with minimal thermal impact, making it particularly valuable for heat-sensitive materials. The price consideration includes the laser source, control system, marking software, and necessary safety equipment. Modern UV laser marking systems incorporate advanced features such as automated material handling, vision systems for quality control, and user-friendly interfaces. The investment also covers installation, training, and often initial maintenance services. When evaluating UV laser marking prices, it's essential to consider the system's marking speed, which typically ranges from 300 to 3000 characters per second, and the marking field size, usually between 50x50mm to 300x300mm.