metal laser marking machine price

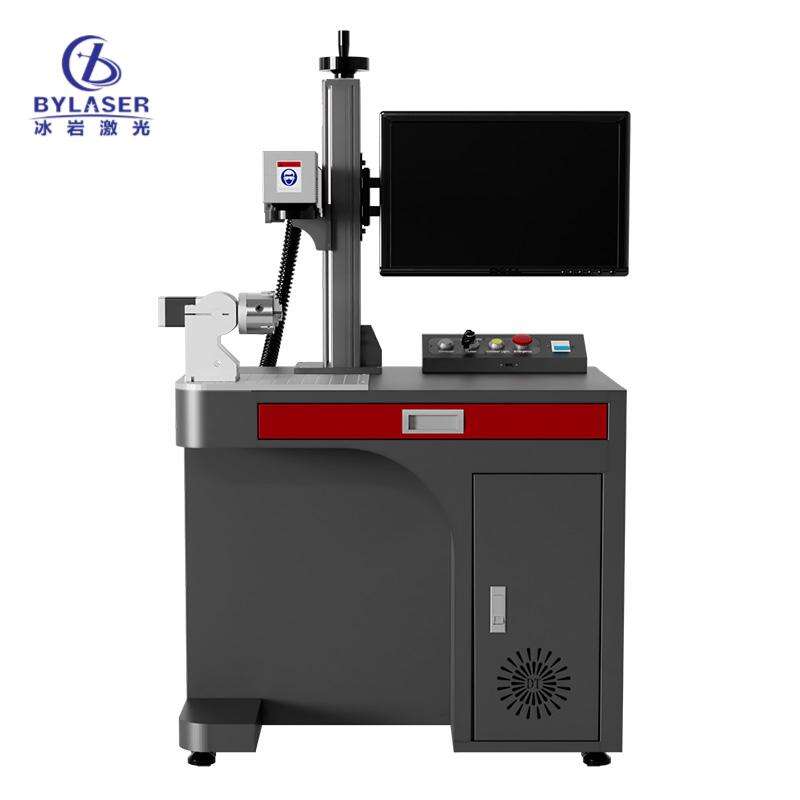

Metal laser marking machine pricing represents a significant investment consideration for businesses seeking efficient and precise marking solutions. These machines typically range from $3,000 to $30,000, depending on their specifications and capabilities. The price variation reflects different power outputs (20W to 100W), marking areas (from 110x110mm to 300x300mm), and advanced features such as automatic focusing systems and rotary attachments. Modern metal laser marking machines incorporate fiber laser technology, offering exceptional precision and durability for marking various metallic surfaces. These systems operate through precise laser beam control, creating permanent, high-contrast marks without damaging the material's surface. The price point often correlates with marking speed capabilities, ranging from 100 to 10,000 mm/s, and the inclusion of user-friendly software interfaces. Applications span across industries, from automotive parts marking to jewelry customization, medical device labeling, and industrial component tracking. The investment considerations should account for additional features like automatic door systems, fume extraction units, and warranty coverage, which can impact the final price.