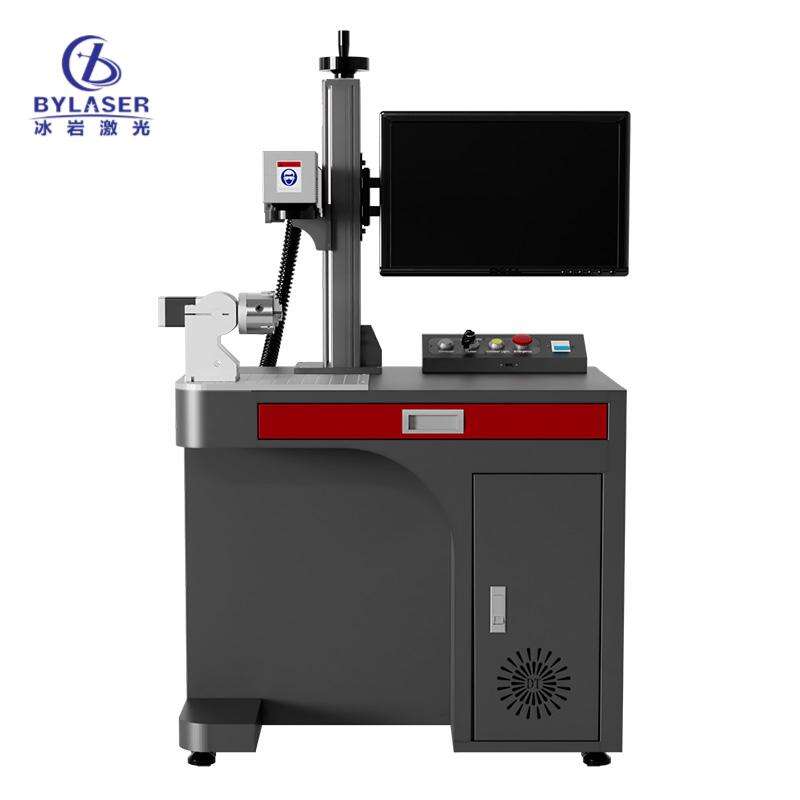

laser marking machine for wood

The laser marking machine for wood represents a cutting-edge solution in woodworking technology, combining precision engineering with digital control systems. This advanced equipment utilizes focused laser beams to create permanent, high-quality markings on various wooden surfaces with exceptional accuracy. The machine operates through a sophisticated computer-controlled system that translates digital designs into precise laser movements, enabling intricate patterns, logos, text, and artistic designs to be permanently etched onto wood surfaces. The technology employs either CO2 or fiber laser sources, with power outputs ranging from 20W to 100W, suitable for different wood types and marking depths. The marking process is non-contact, ensuring no mechanical stress on the material while maintaining the natural beauty of the wood grain. The machine's versatility allows for marking on both flat and curved wooden surfaces, making it ideal for furniture manufacturing, craft production, and industrial wood processing. Advanced features include automatic focus adjustment, multiple marking modes, and integrated cooling systems for continuous operation. The machine's software interface supports various file formats, including AI, DXF, BMP, and JPG, enabling seamless integration with existing design workflows and production systems.