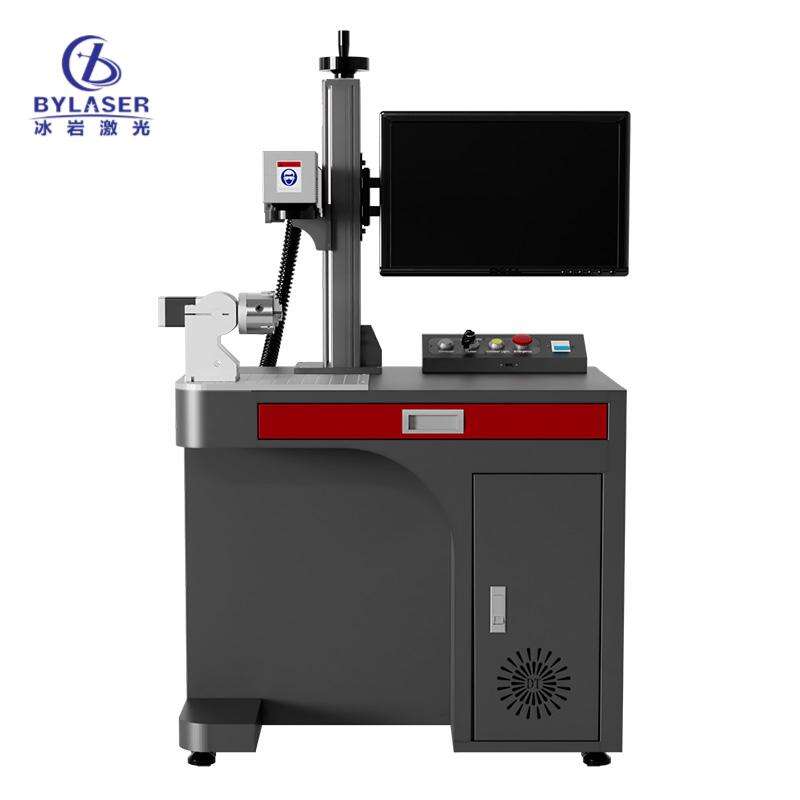

metal fiber laser marking

Metal fiber laser marking represents a cutting-edge technology that utilizes a concentrated beam of light to create permanent, high-precision markings on various metal surfaces. This advanced system employs a fiber-optic laser source that generates an intense, focused beam capable of producing detailed engravings, logos, serial numbers, and other identifying marks on metallic materials. The technology operates by directing a high-powered laser beam through a series of precision optical components, creating microscopic alterations on the material's surface. These alterations can range from surface-level etching to deeper engravings, depending on the specific requirements. The system's precision control allows for marking sizes from microscopic details to larger designs, making it versatile for various industrial applications. Metal fiber laser marking systems are extensively used in automotive manufacturing, aerospace components, medical devices, and consumer electronics, where permanent identification and traceability are crucial. The technology offers exceptional marking quality with high contrast and clarity, ensuring long-lasting results that resist wear and environmental factors. The process is entirely digital, allowing for quick adjustments to marking patterns and seamless integration with production lines, making it an essential tool in modern manufacturing processes.