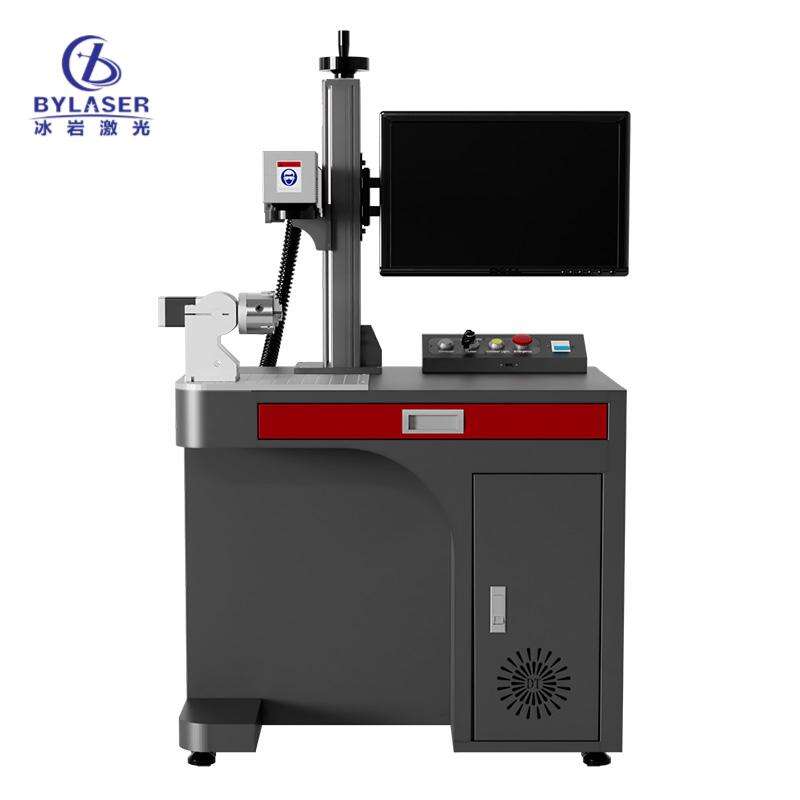

laser to remove rust for sale

The laser rust removal system represents a cutting-edge solution in surface cleaning technology, offering a precise and environmentally friendly approach to rust elimination. This advanced system utilizes high-powered laser beams that effectively ablate rust and oxidation layers without damaging the underlying material. Operating at frequencies optimized for rust removal, the laser system can process various surface types, from delicate antiques to industrial equipment. The technology employs a sophisticated scanning mechanism that ensures uniform coverage and consistent results across the entire treatment area. With adjustable power settings ranging from 20W to 1000W, users can customize the cleaning intensity based on the specific requirements of each project. The system includes advanced safety features, including automatic shut-off mechanisms and protective shields, ensuring operator safety throughout the cleaning process. Its portable design allows for easy transportation and setup in different work environments, while the intuitive control interface enables operators to monitor and adjust parameters in real-time. The system also features an integrated air filtration system that captures and contains removed particles, maintaining a clean work environment and complying with environmental regulations.