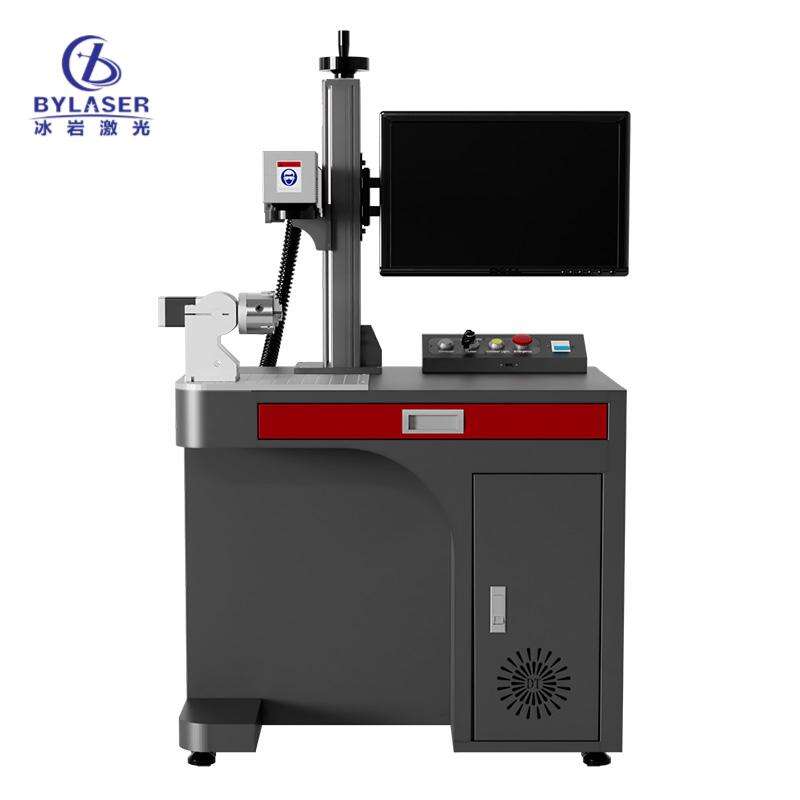

high precision fiber laser cutting machine manufacturers

High precision fiber laser cutting machine manufacturers represent the forefront of modern industrial cutting technology, offering state-of-the-art solutions for diverse manufacturing needs. These manufacturers specialize in developing and producing advanced fiber laser systems that deliver exceptional cutting precision, reaching accuracies of up to 0.003mm. Their machines utilize high-powered fiber lasers, typically ranging from 1000W to 12000W, capable of processing various materials including carbon steel, stainless steel, aluminum, brass, and copper. The cutting-edge systems incorporate advanced features such as automatic focus control, intelligent nesting software, and real-time monitoring capabilities. These manufacturers emphasize research and development, continuously improving their technology to meet evolving industry demands. They integrate sophisticated CNC control systems with user-friendly interfaces, enabling seamless operation and programming. The machines feature robust construction with precision linear guides and advanced motion control systems, ensuring stability during high-speed cutting operations. Additionally, these manufacturers provide comprehensive solutions including automatic loading and unloading systems, advanced dust collection mechanisms, and efficient cooling systems, making their machines suitable for both small-scale operations and large industrial applications.