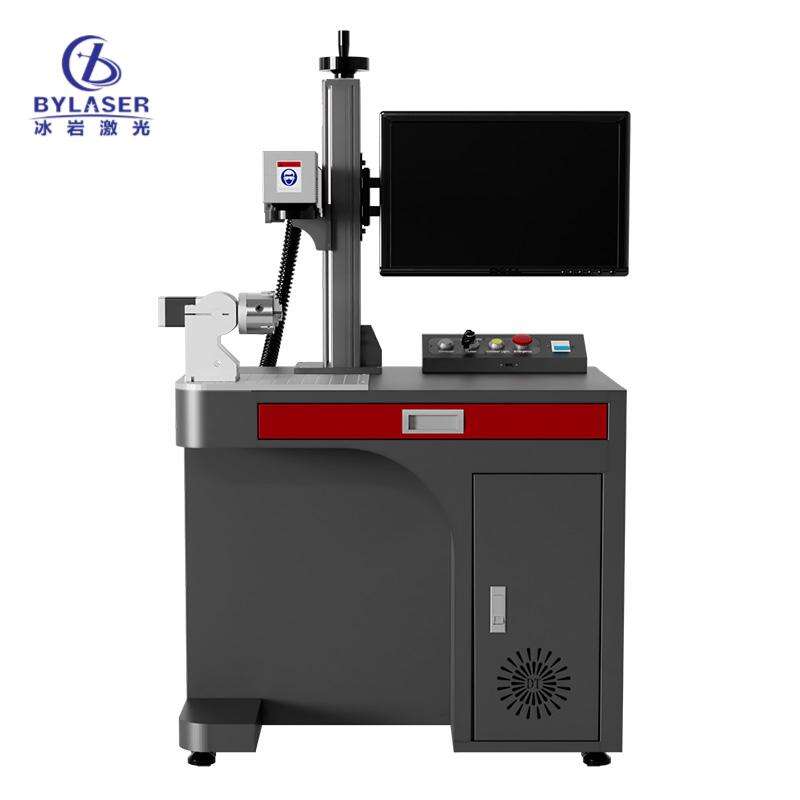

fiber laser metal marking machine

The fiber laser metal marking machine represents a cutting-edge solution in industrial marking technology, combining precision, speed, and versatility in one comprehensive system. This advanced equipment utilizes a high-powered fiber laser beam to create permanent, high-contrast marks on various metal surfaces. The machine operates by focusing a concentrated beam of light that interacts with the material surface, creating precise and durable markings without damaging the underlying structure. The system excels in producing everything from simple text and serial numbers to complex logos and barcodes, with exceptional clarity and consistency. The machine's core technology employs a fiber-optic delivery system that ensures minimal maintenance requirements and extended operational lifetime. It features an advanced cooling system that maintains optimal performance during extended operation periods, while its user-friendly interface allows for easy programming and operation. The marking process is entirely digital, enabling quick adjustments and modifications to marking parameters, making it ideal for both small batch productions and high-volume manufacturing environments. With its ability to mark on curved surfaces and irregular shapes, the machine demonstrates remarkable adaptability across various industrial applications, from automotive parts to medical devices, electronic components, and jewelry items.