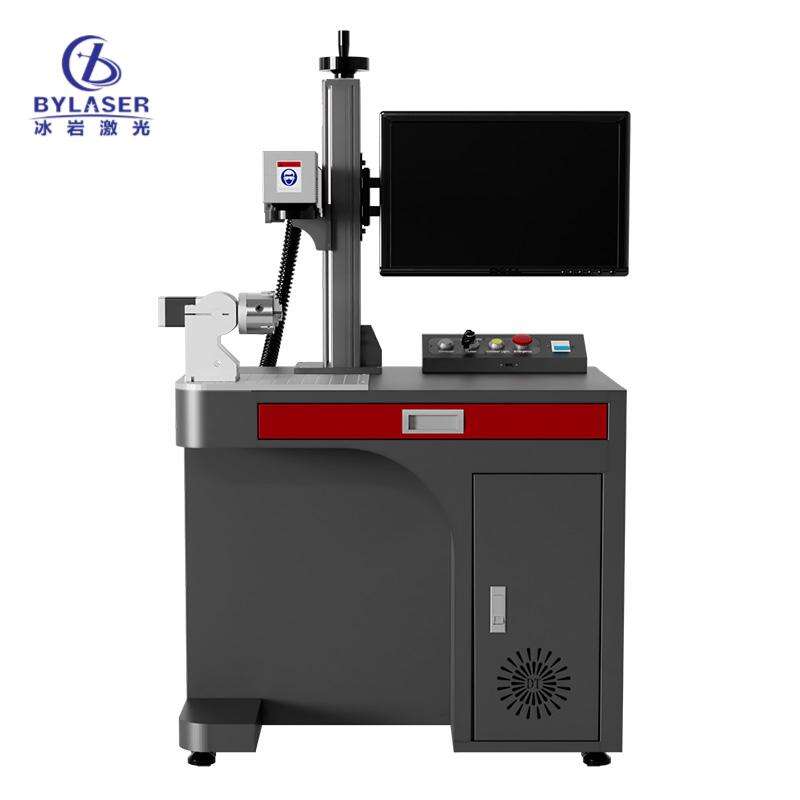

fiber laser engraving acrylic

Fiber laser engraving acrylic represents a cutting-edge technology that combines precision, efficiency, and versatility in material processing. This advanced system utilizes a concentrated beam of light generated by fiber laser technology to create intricate designs, markings, and patterns on acrylic surfaces. The process works by directing a high-powered laser beam that interacts with the acrylic material at a molecular level, causing controlled material removal or surface modification. The technology offers exceptional control over marking depth, speed, and intensity, enabling both surface engraving and deep marking capabilities. One of the most significant advantages of fiber laser engraving is its ability to produce high-contrast, permanent markings without damaging the surrounding material. The system operates with remarkable precision, capable of creating detailed designs as small as 0.1mm in size. The non-contact nature of the process ensures that no mechanical stress is applied to the acrylic, preventing material deformation or cracking. Applications span across various industries, including signage, awards and trophies, architectural elements, retail displays, and custom product manufacturing. The technology's compatibility with both clear and colored acrylic materials makes it an invaluable tool for creating sophisticated designs and functional markings in modern manufacturing processes.