fiber laser cleaning machine price

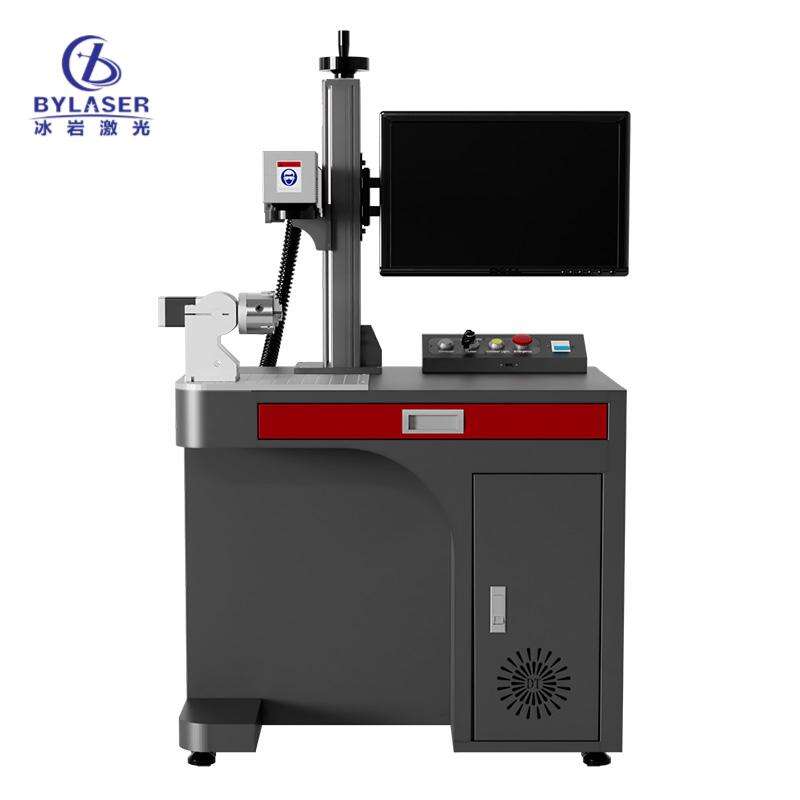

The fiber laser cleaning machine price reflects a significant investment in advanced surface preparation technology. These machines typically range from $30,000 to $100,000, depending on power capacity and additional features. The pricing structure correlates directly with the machine's capability to efficiently remove rust, paint, oil, and other contaminants from various surfaces using high-precision laser technology. Operating at different power levels from 50W to 2000W, these machines deliver exceptional cleaning results without damaging the underlying material. The price point includes essential components such as the laser generator, scanning system, control unit, and cooling system. Modern fiber laser cleaning machines incorporate advanced features like adjustable cleaning widths, variable frequency settings, and programmable cleaning patterns. The investment covers sophisticated software interfaces that allow operators to customize cleaning parameters for different applications. These machines find widespread use in automotive manufacturing, aerospace maintenance, mold cleaning, and heritage conservation. The price also factors in safety features, including protective enclosures and emergency shutdown systems, ensuring operator safety during operation.