The industrial cleaning landscape has undergone a remarkable transformation with the introduction of laser cleaner machines. These innovative devices represent a quantum leap in surface treatment technology, offering unprecedented precision and efficiency in removing contaminants, rust, paint, and other unwanted materials from various surfaces. As industries increasingly prioritize environmental responsibility and operational efficiency, laser cleaner machines have emerged as a game-changing solution that addresses both these crucial aspects.

Traditional cleaning methods often involve abrasive materials, harsh chemicals, or mechanical processes that can damage delicate surfaces and pose environmental risks. In contrast, a laser cleaner machine harnesses the power of focused light energy to achieve superior cleaning results without physical contact or harmful substances. This revolutionary approach is reshaping how industries approach surface preparation and maintenance tasks.

One of the most significant advantages of using a laser cleaner machine is its environmentally friendly nature. Unlike conventional cleaning methods that rely on chemical solvents or abrasive materials, laser cleaning generates minimal waste and requires no additional cleaning agents. The process produces only the removed contaminants as waste, which can be easily collected and disposed of properly. This dramatically reduces the environmental impact of cleaning operations while eliminating the need for handling and storing hazardous cleaning materials.

Worker safety is another crucial benefit of laser cleaning technology. Operators are not exposed to harmful chemicals or dust particles, and the risk of injury from mechanical cleaning tools is eliminated. Modern laser cleaner machines come equipped with advanced safety features, including automatic shut-off mechanisms and protective enclosures, ensuring optimal operator protection during the cleaning process.

The level of precision offered by a laser cleaner machine is unmatched in the surface treatment industry. The technology allows for exact control over the cleaning area, depth, and intensity, ensuring that only unwanted materials are removed while preserving the integrity of the underlying surface. This precision is particularly valuable when working with delicate or historically significant items that require careful restoration.

Operators can fine-tune various parameters such as laser power, pulse frequency, and scanning speed to achieve optimal results for different applications. This level of control ensures consistent cleaning quality across large surfaces and enables the treatment of complex geometries that would be challenging to clean using traditional methods.

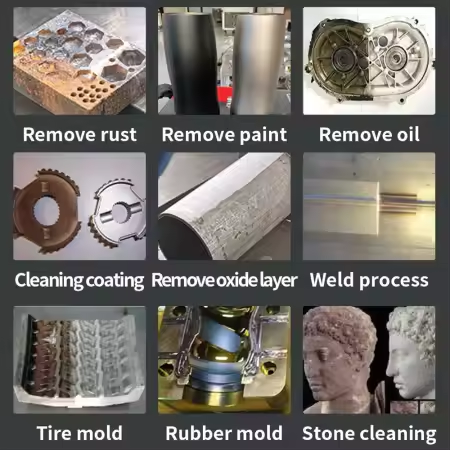

In manufacturing environments, a laser cleaner machine proves invaluable for various applications. From preparing surfaces for coating or welding to removing production residues, the technology offers fast and efficient cleaning solutions that integrate seamlessly into production lines. The absence of chemical cleaning agents means there's no need for drying time or additional surface preparation steps, contributing to improved production efficiency.

The ability to automate laser cleaning processes further enhances its value in industrial settings. Modern laser cleaner machines can be integrated with robotic systems and programmed to perform repetitive cleaning tasks with consistent quality, reducing labor costs and increasing throughput. This automation capability makes laser cleaning particularly attractive for high-volume manufacturing operations.

The restoration sector has embraced laser cleaning technology for its ability to gently remove decades or even centuries of accumulated dirt and contaminants from valuable artifacts and architectural elements. A laser cleaner machine can effectively treat delicate surfaces without causing any mechanical stress or chemical alterations to the underlying material. This preservation-friendly approach has made laser cleaning the preferred method for many conservation projects worldwide.

Historic buildings, sculptures, and artwork can be restored to their former glory while maintaining their historical integrity. The non-contact nature of laser cleaning eliminates the risk of physical damage that can occur with traditional cleaning methods, making it an ideal choice for precious heritage conservation work.

While the initial investment in a laser cleaner machine may be higher compared to traditional cleaning equipment, the long-term cost benefits are substantial. The technology requires minimal consumables, reducing ongoing operational expenses. Additionally, the elimination of chemical cleaning agents and abrasive materials leads to significant savings in material costs and storage requirements.

The durability and low maintenance requirements of laser cleaning systems contribute to their cost-effectiveness. With proper care, a laser cleaner machine can operate reliably for many years, requiring only routine maintenance and occasional replacement of certain components. This reliability translates to reduced downtime and maintenance costs over the equipment's lifetime.

The speed and efficiency of laser cleaning operations contribute significantly to overall productivity improvements. The process is typically faster than traditional cleaning methods, especially for complex or detailed work. The ability to clean surfaces in a single pass, without the need for secondary cleaning or drying steps, reduces processing time and increases throughput.

Labor efficiency is another key advantage, as operators can clean larger areas more quickly and with less physical effort compared to manual cleaning methods. The precision and consistency of laser cleaning also reduce the need for rework, further improving overall operational efficiency.

A laser cleaner machine operates by emitting high-energy laser pulses that create rapid thermal expansion in the contamination layer, causing it to break apart and vaporize. The process is selective, targeting only the unwanted material while leaving the underlying surface unaffected. The system typically includes laser source, beam delivery optics, and scanning mechanisms to control the cleaning process.

Laser cleaning is suitable for a wide range of materials including metals, stone, concrete, wood, and various composites. The technology can effectively remove rust, oxidation, paint, oils, biological growth, and other contaminants. However, the specific laser parameters must be adjusted according to the material and type of contamination being treated.

Yes, laser cleaning is environmentally friendly as it doesn't require chemicals or produce hazardous waste. The only byproducts are the removed contaminants, which can be collected through integrated vacuum systems. The process generates minimal dust and no chemical residues, making it a sustainable choice for industrial cleaning applications.