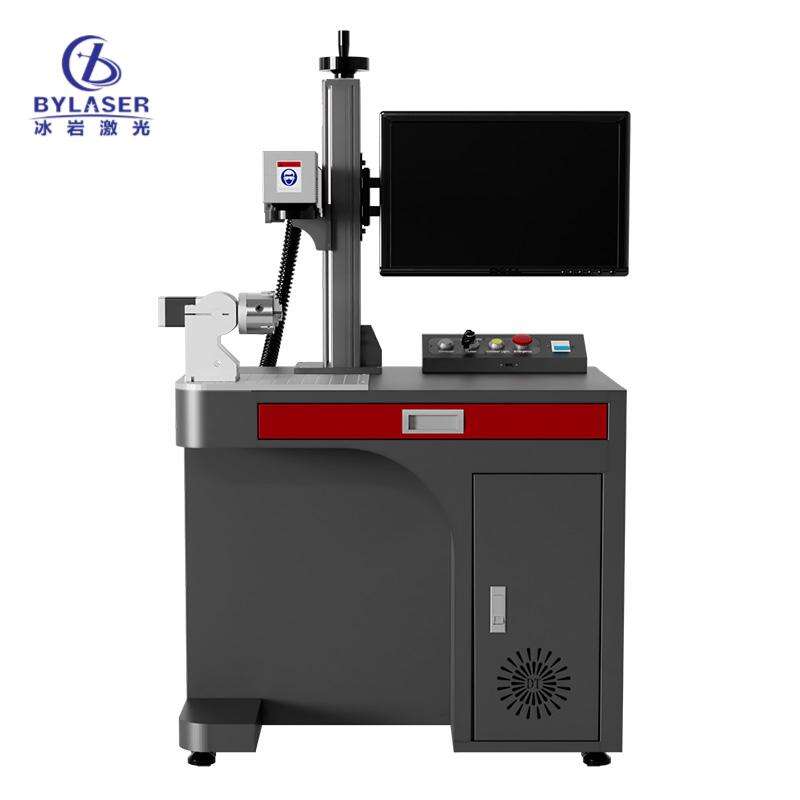

metal laser cleaning

Metal laser cleaning represents a cutting-edge technology that revolutionizes surface preparation and maintenance in industrial applications. This innovative process utilizes high-powered laser beams to remove contaminants, rust, paint, and oxidation from metal surfaces without causing damage to the underlying material. The technology operates by delivering precise, concentrated light energy that vaporizes unwanted substances while preserving the base metal's integrity. The process is entirely computer-controlled, allowing for exceptional precision and repeatability in cleaning operations. The system can be adjusted to accommodate various metal types and contamination levels, making it versatile across industries including automotive manufacturing, aerospace, electronics, and heritage conservation. Unlike traditional cleaning methods, laser cleaning requires no chemicals or abrasives, making it an environmentally friendly solution. The technology employs specific wavelengths and power settings that effectively target unwanted materials while leaving the base metal untouched. This selective cleaning capability ensures optimal results without risk of surface damage or material loss. The process is particularly valuable for delicate or high-value components where conventional cleaning methods might prove too aggressive or ineffective.