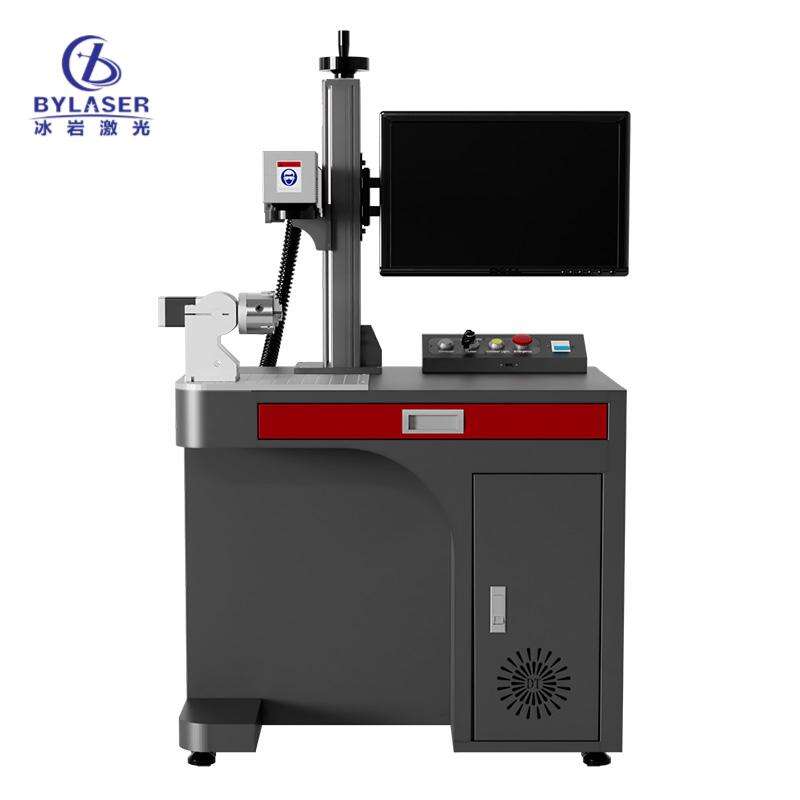

laser rust remover

The laser rust remover represents a cutting-edge solution in surface cleaning technology, utilizing precise laser beams to effectively eliminate rust, corrosion, and oxidation from various metal surfaces. This advanced system operates by directing concentrated laser energy onto the rusted area, causing the rust layer to absorb the energy and effectively separate from the base material. The process, known as laser ablation, vaporizes the rust while leaving the underlying metal completely undamaged. Operating at frequencies ranging from 20 to 100 kHz, the laser rust remover can handle surfaces of varying sizes and complexities. The technology incorporates smart scanning systems that automatically adjust the laser intensity based on the rust severity and metal type. Users can select from multiple operating modes, including pulse and continuous wave options, to achieve optimal cleaning results. The device features an integrated air filtration system that captures and contains the vaporized rust particles, ensuring a clean and safe working environment. This versatile tool finds extensive applications across various industries, from automotive restoration and manufacturing to historical preservation and marine equipment maintenance. The system's precision control allows for detailed work on intricate surfaces, making it equally effective for both large-scale industrial applications and delicate restoration projects.