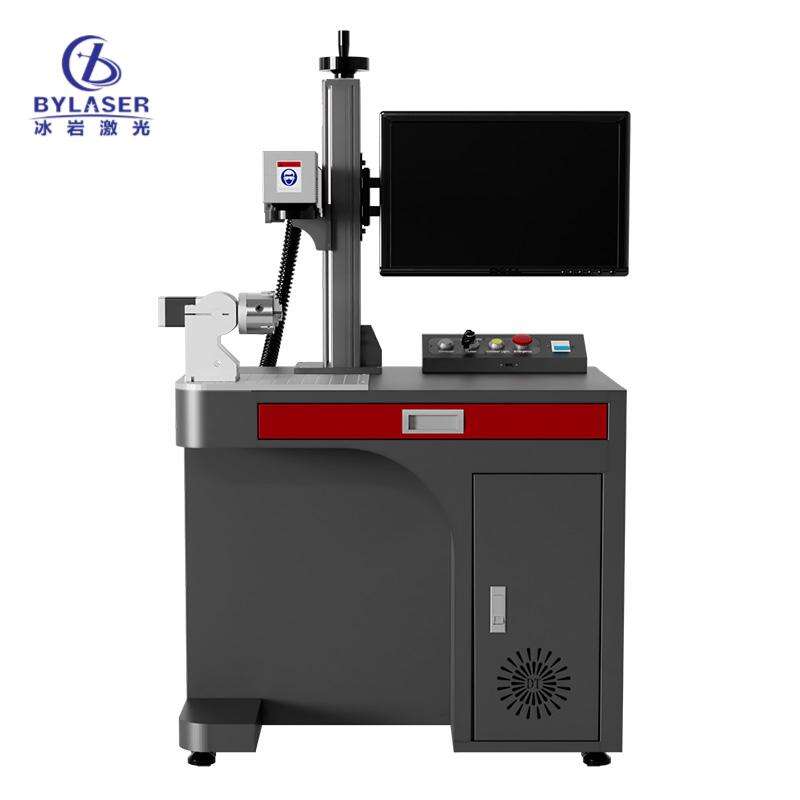

laser rust removal machine

The laser rust removal machine represents a cutting-edge solution in surface cleaning technology, utilizing advanced laser technology to effectively eliminate rust, corrosion, and surface contaminants from various materials. This innovative system employs high-precision laser beams that target and vaporize rust particles while leaving the underlying material completely intact. Operating at frequencies of up to 100kHz, the machine delivers concentrated energy that breaks down rust at a molecular level, ensuring thorough cleaning without any chemical residues or abrasive materials. The system features adjustable power settings ranging from 50W to 500W, allowing operators to customize the cleaning intensity based on the specific requirements of each project. The machine's sophisticated optical system includes precision-engineered scanning heads that enable uniform coverage across both flat and curved surfaces, ensuring consistent results every time. Additionally, the laser rust removal machine incorporates advanced safety features, including automatic shut-off mechanisms and protective enclosures, making it suitable for use in various industrial environments. Its applications span across multiple sectors, from automotive restoration and manufacturing to historical preservation and marine maintenance, offering a versatile solution for diverse cleaning needs.